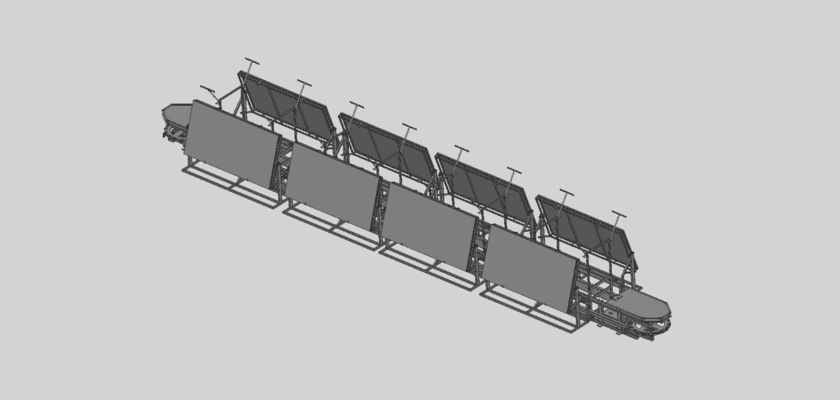

En Línea de producción de manijas de alambre para automóviles is a state-of-the-art manufacturing system designed to streamline the production of wire handles used in automotive applications. This automated production line ensures efficiency, precision, and scalability, making it a vital asset for manufacturers in the automotive industry. The system is designed to meet high-volume demands while maintaining consistent quality standards.

Características principales:

- Alta eficiencia: The production line automates multiple stages of the wire handle manufacturing process, increasing output and reducing labor costs.

- Ingeniería de precisión: Equipped with advanced machinery and control systems, this line ensures precise handling and shaping of wire handles, minimizing defects.

- Adaptable to Multiple Designs: Capable of producing wire handles of various sizes and specifications, the production line is versatile and can be tailored to different automobile designs.

- Durable y confiable: Built with high-quality materials, the system is designed for long-term use, with minimal maintenance requirements and a robust performance record.

- Eficiencia energética: Designed with energy-saving technology, the line optimizes power consumption while maintaining high production efficiency.

Descargar el dibujo of the Automobile Wire Handle Production Line to gain detailed insights into its design, mechanics, and layout. Ideal for engineers and production planners, this drawing will help optimize the setup and efficiency of your production process.