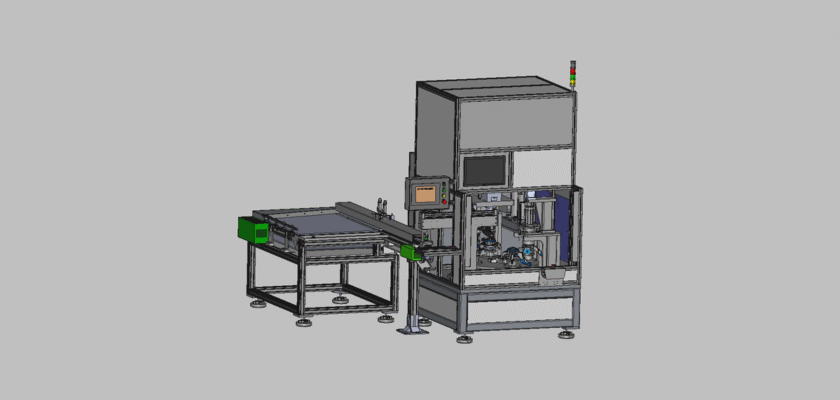

Adéntrese en el mundo de la fabricación de precisión con nuestro plano gratuito de la máquina automática de ajuste a presión de rodamientos. Este equipo especializado es fundamental en las industrias que requieren un ensamblaje de rodamientos de alta velocidad y precisión. Está diseñado para... Insertar automáticamente cojinetes en carcasas o ejes Con una velocidad, precisión y repetibilidad inigualables. Al eliminar la mano de obra, garantiza una fuerza de prensado constante, reduce el tiempo de montaje y aumenta significativamente la producción. Este plano detallado es un recurso invaluable para ingenieros, fabricantes y estudiantes que quieran comprender la compleja mecánica y los principios de automatización detrás de esta herramienta de producción esencial.

Nuestro completo plano ofrece una visión clara de los componentes principales de la estación de trabajo: un marco robusto, una prensa o actuador de precisión, un sistema automatizado de alimentación de piezas y un sistema de control integrado. Comprenderá a fondo cómo estos elementos funcionan en perfecta sincronización, garantizando que cada rodamiento se ensamble según las especificaciones exactas en todo momento. Tanto si es un profesional encargado de diseñar una nueva línea de montaje, un estudiante de mecatrónica o un aficionado que construye un prototipo, este plano le ofrece los conocimientos básicos que necesita. Descárguelo gratis y dé el primer paso hacia un ensamblaje más inteligente y eficiente.

Características principales

- Ajuste a presión automatizado: El plan destaca un sistema que utiliza un prensa neumática o hidráulica para insertar rodamientos automáticamente con fuerza y profundidad controladas.

- Alimentación de piezas de precisión: Aprenda cómo un alimentador vibratorio o se utiliza otro mecanismo para clasificar y presentar automáticamente los cojinetes y las carcasas a la estación de ensamblaje, lo que garantiza un flujo continuo.

- Sensores integrados: El diseño incluye disposiciones para sensores de fuerza y posición que proporcionan retroalimentación en tiempo real al sistema de control, garantizando que el ensamblaje se realice correctamente.

- Operación de alta velocidad: La estación de trabajo está diseñada para brindar velocidad y eficiencia, demostrando cómo lograr un alto rendimiento con una mínima intervención humana.

- Diseño versátil: El diseño se puede adaptar a una amplia gama de tipos y tamaños de rodamientos simplemente cambiando las herramientas y accesorios de montaje.