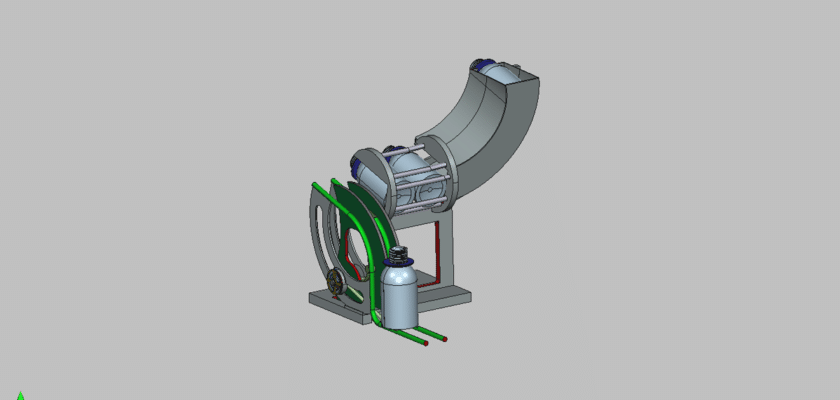

En Beverage Bottle Conveyor Drawing illustrates a specialized conveyor system designed specifically for the efficient transport of beverage bottles in production and packaging environments. This drawing highlights the key components, structural features, and operational capabilities essential for handling bottles safely and effectively.

Características principales:

- Belt Design: The conveyor features a durable belt tailored for beverage bottles, often made from food-grade materials like PVC or polyurethane. The belt is designed to provide excellent grip and stability, minimizing the risk of bottle slippage during transport.

- Modular Frame Structure: The drawing depicts a robust frame constructed from high-strength materials such as stainless steel or aluminum. This modular design allows for easy customization and integration into existing production lines, ensuring stability and durability.

- Bottle Guides and Side Rails: Integrated guides and side rails are included in the design to keep bottles properly aligned during transport, preventing collisions and ensuring smooth movement through the conveyor system.

- Drive Mechanism: The drive assembly, consisting of a motor, pulleys, and gear systems, is illustrated, providing reliable power to the conveyor belt. This mechanism is essential for maintaining consistent speed and efficient operation.

- Adjustable Speed Control: Features variable speed control that allows operators to customize the conveyor speed based on the production requirements, optimizing workflow and minimizing downtime.

- Safety Features: The drawing highlights essential safety mechanisms, such as emergency stop buttons, safety guards, and properly marked access points, ensuring a safe working environment for operators.

- Discharge and Intake Points: Clearly marked discharge and intake points in the drawing facilitate easy loading and unloading of bottles, improving the overall efficiency of the production line.

Applications:

- Beverage Production: Ideal for transporting various types of beverage bottles, including soft drinks, juices, and bottled water, throughout the production and bottling process.

- Packaging: Facilitates the movement of filled bottles to packaging stations, ensuring efficient sorting, packing, and labeling operations.

- Logistics and Distribution: Plays a critical role in sorting and distributing finished products within warehouses or distribution centers, optimizing inventory management.

- Recycling Facilities: Can be adapted for use in recycling operations, transporting empty or discarded bottles for processing.

Overall Impression:

En Beverage Bottle Conveyor Drawing serves as a crucial visual tool for engineers, designers, and operators involved in the development, implementation, and maintenance of beverage handling systems. By detailing the essential components and their interrelationships, this drawing aids in ensuring efficient and safe transport of beverage bottles, ultimately contributing to improved productivity and operational efficiency in beverage production and packaging environments. Understanding this drawing allows stakeholders to make informed decisions regarding the design and functionality of conveyor systems tailored for beverage applications.