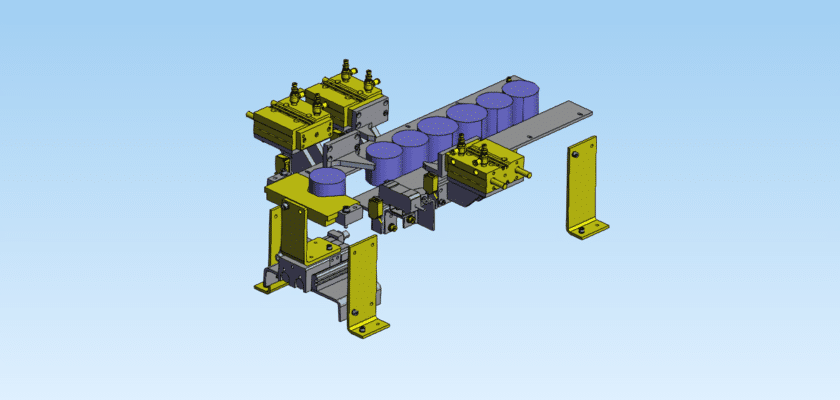

Ensure operational safety and precise stopping power with our professional technical documentation for the Brake Mechanism. This assembly is a critical safety component in various industrial applications, including conveyors, cranes, and automated machinery. Designed for high-frequency engagement and thermal stability, this mechanism provides the necessary friction to decelerate or hold a load securely in place. Having access to these detailed schematics allows engineers to integrate failsafe braking solutions that protect both personnel and expensive equipment.

The provided dibujo files offer an exhaustive look at the internal linkage, spring-return systems, and friction material interfaces. By analyzing the leverage ratios and torque ratings mapped out in these blueprints, designers can calculate the exact stopping distance and clamping force required for their specific load profiles. We provide these high-fidelity CAD resources for free to help you eliminate design guesswork and ensure your machinery meets stringent safety standards.

Our files are formatted for seamless import into professional 3D modeling environments, allowing for accurate interference checks and kinetic simulations. Whether you are designing an electromagnetic, hydraulic, or mechanical disc brake, these drawings provide the structural foundation needed for a robust build. Download this comprehensive package today to enhance the reliability and safety of your mechanical drive systems.

Características principales:

- High-Torque Friction Interface: Optimized pad and rotor geometry designed for maximum grip and minimal wear over time.

- Failsafe Engagement: Includes detailed spring-applied, power-released configurations to ensure the brake locks during power loss.

- Thermal Dissipation Design: Features cooling fins and airflow pathways to prevent brake fade during repetitive high-load cycles.

- Adjustable Wear Compensation: Integrated adjustment points to maintain consistent air gaps as friction linings naturally wear down.

- Standardized Mounting Flange: Designed for universal compatibility with standard NEMA or IEC motor frames.