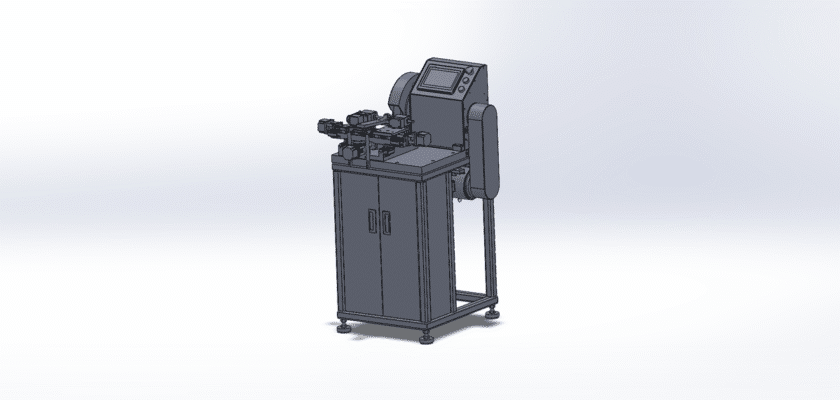

Descubra el recurso definitivo para la ingeniería de precisión con nuestro exclusivo Rectificadora CNC dibujo, disponible para descarga gratuitaEste valioso dibujo técnico ofrece una visión detallada de una rectificadora CNC de alto rendimiento, una herramienta crucial en la fabricación moderna para lograr acabados superficiales superiores y tolerancias ultraestrechas. Tanto si es estudiante, maquinista profesional como ingeniero, este dibujo es una pieza esencial en su biblioteca técnica. Ofrece una visión completa de los complejos mecanismos internos y sistemas de control de la máquina, ayudándole a comprender cómo funcionan estas potentes herramientas para producir componentes impecables. Al descargar este dibujo, adquirirá una comprensión fundamental de los principios del rectificado CNC, desde el control automatizado hasta la eliminación precisa de material. Es una herramienta indispensable para fines educativos, proyectos de diseño de máquinas o simplemente para satisfacer su curiosidad sobre el funcionamiento interno de la maquinaria industrial avanzada.

Características principales:

- Precisión excepcional: El dibujo destaca los componentes que permiten una precisión submicrónica, sello distintivo del rectificado CNC. Muestra el bastidor rígido, las guías lineales de alta precisión y los ejes servocontrolados que trabajan en conjunto para eliminar las vibraciones y garantizar resultados repetibles.

- Sistema de control automatizado: Los planos detallados ilustran el sofisticado controlador CNC, el "cerebro" de la máquina. Esta sección ofrece información sobre cómo la programación en código G se traduce en movimientos precisos y automatizados de la muela y la pieza de trabajo, reduciendo drásticamente el error humano y aumentando la eficiencia.

- Sistemas de refrigeración y lubricación: El dibujo incluye una vista detallada de los sistemas integrados de refrigeración y lubricación. Estos son cruciales para disipar el inmenso calor generado durante el rectificado y para mantener la integridad de la pieza, garantizando que se mantenga dentro de las tolerancias dimensionales y evitando daños a los componentes de la máquina.

- Diseño versátil: Nuestro dibujo muestra un diseño adaptable a diversas operaciones de rectificado, como el rectificado de superficies, cilíndricos y de herramientas. Su versátil diseño permite mecanizar una amplia gama de materiales y formas complejas, lo que lo convierte en un recurso versátil para cualquier taller o entorno de fabricación.