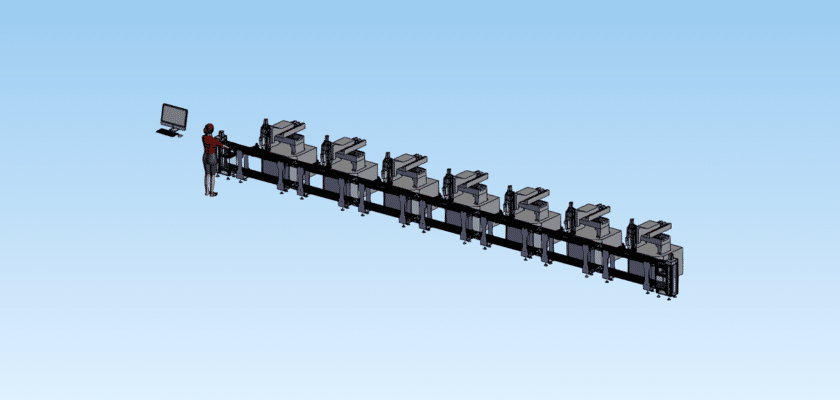

Transform your factory floor into a high-efficiency powerhouse by choosing to download our CNC Machining Line drawing. Unlike standalone units, a CNC machining line represents a fully integrated ecosystem where multiple machining centers, robotic arms, and transport systems work in perfect synchronization. This technical drawing provides a comprehensive macro-view of the entire production flow, detailing the mechanical and digital interfaces required to move workpieces from raw casting to finished parts without manual intervention. It is a critical asset for industrial engineers planning large-scale manufacturing projects or optimizing existing throughput.

By utilizing this professional CAD resource, you can analyze the spatial arrangement and logistical sequencing of an automated line. The drawing highlights the critical connection points between individual CNC stations and the centralized control units, ensuring that coolant systems, chip management, and power distribution are scaled appropriately for continuous operation. Whether you are producing complex automotive engine blocks or high-volume consumer components, these schematics offer the foundational data needed to minimize bottlenecks and maximize equipment effectiveness (OEE). Download this document to gain the technical clarity necessary for building a future-proof, scalable manufacturing environment.

Características principales:

- Manejo automatizado de materiales: Detailed layouts for gantry loaders or 6-axis robotic interfaces that facilitate high-speed workpiece transfer between machining cells.

- Centralized Coolant and Filtration: A comprehensive piping and tank architecture designed to service multiple machines from a single high-capacity filtration unit.

- Modular Station Configuration: A flexible structural design that allows for the addition or removal of machining modules based on evolving production requirements.

- Synchronized Control Architecture: Insights into the integration of Master PLC systems that coordinate the timing and safety protocols across the entire line.

- Integrated Inspection Stations: Designated zones within the line for automated in-process gauging and CMM verification to ensure zero-defect output.