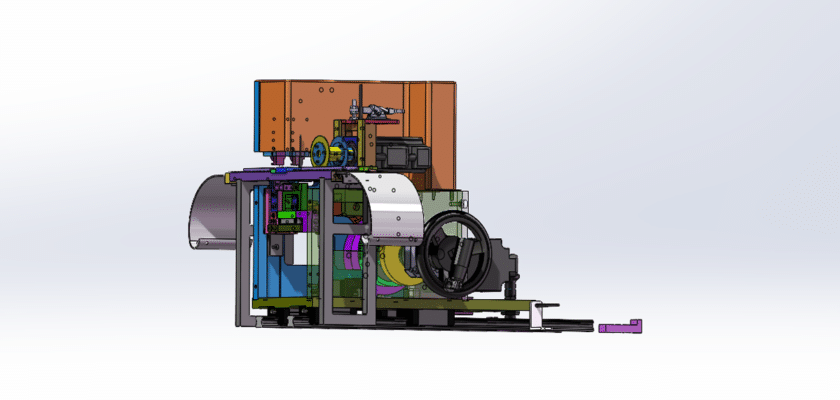

This detailed drawing of the Connector Bending Machine illustrates a specialized system designed for the precise bending of connectors used in various applications, including electrical, automotive, and industrial sectors. Ideal for manufacturers aiming to enhance productivity, this machine ensures high-quality outputs while maintaining accuracy in connector fabrication.

Características principales del dibujo:

- Automated Bending Process: The machine employs advanced automation technology to streamline the bending of connectors, significantly increasing throughput and reducing manual labor requirements.

- Mecanismo de doblado de alta precisión: Equipped with precision tools and adjustable dies, the machine accurately bends connectors to specified angles and dimensions, ensuring optimal fit and functionality.

- Interfaz de control fácil de usar: The intuitive control panel allows operators to easily program and monitor the bending process, facilitating quick adjustments for different connector designs and specifications.

- Compatibilidad versátil de materiales: Designed to handle a variety of materials, including metals and plastics, making it adaptable for diverse connector types and applications.

- Control de Calidad Integrado: Features built-in inspection systems to ensure that each bent connector meets stringent quality standards, minimizing defects and enhancing overall reliability.

- Construcción robusta y duraderaFabricada con materiales de alta calidad, la máquina está diseñada para durar y ser confiable, lo que garantiza un rendimiento óptimo en entornos de producción exigentes.

This drawing serves as a vital resource for engineers and manufacturers seeking to implement effective and efficient solutions for connector bending in their production lines.