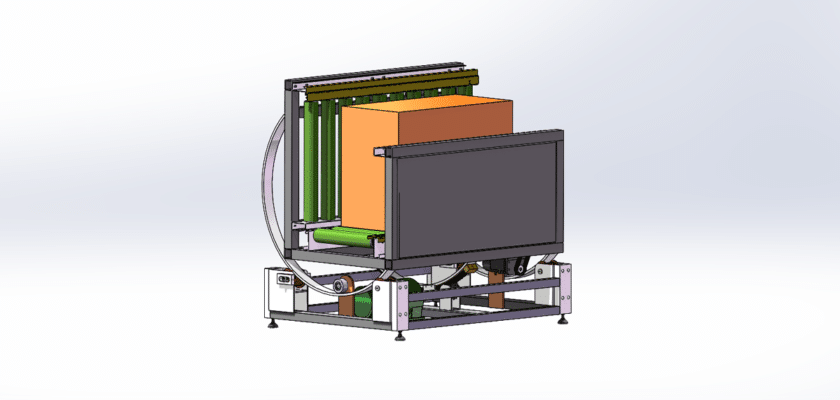

The Conveyor Line Flipper drawing illustrates a specialized device designed to efficiently redirect products on a conveyor line, enhancing workflow and operational flexibility in manufacturing and packaging environments.

Características principales:

- Flipping Mechanism: The drawing details the flipping mechanism, which typically consists of rotating arms or plates that can pivot to change the orientation of items as they pass through the conveyor line.

- Conveyor Integration: Clear visualizations show how the flipper integrates with existing conveyor systems, including connection points and alignment features to ensure smooth operation.

- Control Systems: The drawing includes information on the automated control systems used to operate the flipper, such as sensors that detect the position of items and actuators that initiate the flipping action.

- Safety Features: Important safety components, including emergency stop buttons and safety guards, are highlighted to protect operators and prevent accidents during operation.

- Adjustable Settings: The design may feature adjustable settings for flipping angles and timing, allowing for customization based on the specific requirements of the production process.

- Durable Construction: The drawing emphasizes materials and construction methods used for the flipper, ensuring durability and reliability under continuous operational conditions.

- Maintenance Access: Design considerations for easy access to the flipper’s components for maintenance and troubleshooting are included, promoting efficient upkeep.

This drawing serves as a technical guide for engineers, production managers, and maintenance teams, providing essential information for the design, installation, and operation of conveyor line flippers in various industrial applications.