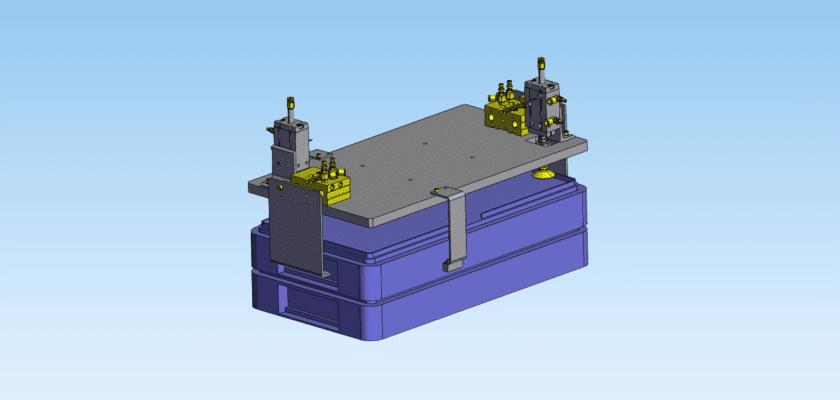

Secure your packaging process with our professional Covered Box Clamping Mechanism drawing. In automated production lines, handling boxes with lids or “covered” tops requires a specialized approach to ensure the cover remains seated while the box is indexed or processed. This technical blueprint provides a comprehensive guide to building a vertical-action clamping system that applies uniform downward pressure, making it ideal for adhesive curing, lid-crimping, or precision labeling applications where zero-movement is a requirement.

The design focuses on a “Soft-Touch” engagement logic, utilizing regulated pneumatic actuators to apply firm but controlled force that prevents crushing the corrugated material. By downloading this drawing from MechStream, you receive a detailed assembly of the pressure plate, the guide rods that prevent lateral shifting, and the sensor mounts for detecting height variations. This mechanism is engineered for high-cycle reliability, ensuring that every box is stabilized perfectly for downstream automation.

Using this professional resource allows your engineering team to avoid the common pitfalls of lid-shifting during transport. The documentation includes specifications for interchangeable clamp faces, allowing you to swap between flat plates for standard boxes or contoured pads for custom lids. Whether you are building a pharmaceutical packaging line or a consumer electronics fulfillment system, this drawing provides the mechanical precision and structural durability required for modern industrial standards.

Características principales:

- Dual-Rod Vertical Stabilization: Features a guided cylinder design that ensures the clamping plate remains perfectly horizontal throughout the stroke.

- Adjustable Pressure Regulation: Designed for integration with precision air regulators to calibrate the holding force for different material strengths.

- Telescopic Height Adjustment: Includes a modular frame design that allows for quick reconfiguration to accommodate boxes of varying depths.

- Non-Slip Contact Surface: Detailed specifications for high-friction, non-marring rubber pads that grip the cover without leaving marks.

- Integrated Safety Interlocks: Features dedicated mounting points for limit switches to ensure the conveyor only moves when the clamp is fully retracted.