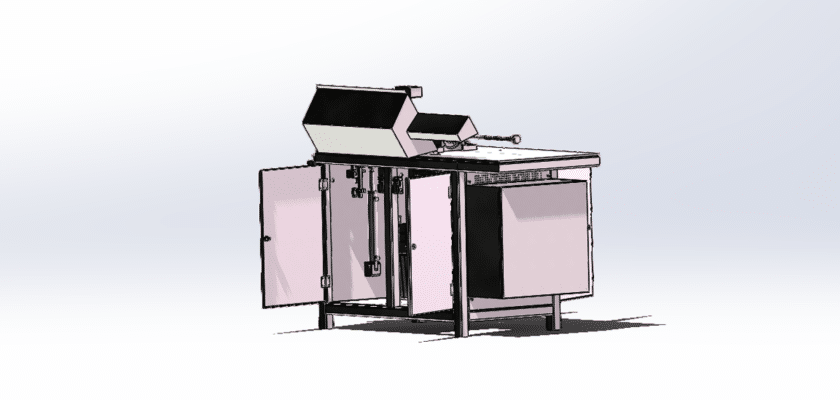

Este dibujo detallado de la máquina crimpadora ilustra un sistema especializado diseñado para el crimpado eficiente de conectores y terminales utilizados en diversas aplicaciones eléctricas y electrónicas. Ideal para fabricantes de sectores como el automotriz, el aeroespacial y las telecomunicaciones, esta máquina mejora la productividad a la vez que garantiza conexiones fiables y de alta calidad.

Características principales del dibujo:

- Proceso de crimpado automatizado:La máquina emplea tecnología de automatización avanzada para agilizar el engarce de conectores, aumentando significativamente el rendimiento y reduciendo los requisitos de mano de obra manual.

- Mecanismo de crimpeado de alta precisiónEquipada con matrices de engarce de precisión y configuraciones ajustables, la máquina garantiza un engarce uniforme y preciso para cumplir con estrictos estándares de calidad.

- Interfaz de control fácil de usar:El panel de control intuitivo permite a los operadores programar y monitorear fácilmente el proceso de engarce, facilitando ajustes rápidos para diferentes tipos y especificaciones de conectores.

- Compatibilidad versátilDiseñado para adaptarse a una amplia gama de tamaños, formas y materiales de conectores, lo que lo hace adaptable para diversas aplicaciones en múltiples industrias.

- Funciones de control de calidad integrado:Incluye sistemas de inspección incorporados para verificar que cada conexión engarzada cumpla con los estándares de calidad, reduciendo los defectos y mejorando la confiabilidad general.

- Construcción robusta y duraderaFabricada con materiales de alta calidad, la máquina está diseñada para durar y ser confiable, lo que garantiza un rendimiento óptimo en entornos de producción exigentes.

Este dibujo sirve como un recurso vital para ingenieros y fabricantes que buscan implementar soluciones de engarce efectivas y eficientes en sus líneas de producción.