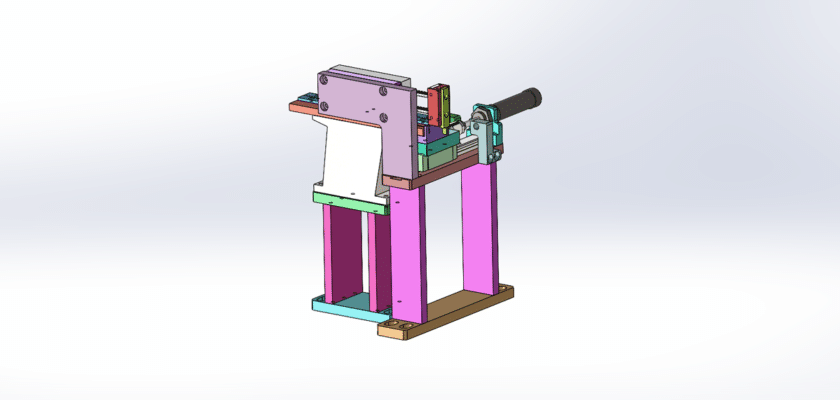

The Cylinder Screw Feed is a specialized mechanism designed to automate the delivery of screws in various manufacturing and assembly processes. This system enhances efficiency by ensuring a consistent and reliable supply of screws, thereby minimizing manual handling and increasing production speed.

Características principales

- Automated Screw Dispensing: The cylinder design allows for the automatic release and positioning of screws, streamlining the fastening process in assembly lines.

- Adjustable Feed Mechanism: Capable of modifying the feed rate according to the specific needs of different applications, ensuring flexibility in operation.

- Diseño compacto y eficiente: Engineered to occupy minimal space while maximizing functionality, making it easy to integrate into existing workflows.

- Construcción duradera: Built from high-quality materials to withstand the rigors of industrial use, ensuring longevity and reliability.

Componentes

- Screw Cylinder: The main body that holds and dispenses screws, designed to facilitate smooth movement and prevent jams.

- Mecanismo de alimentación: A system that controls the release of screws, often utilizing gravity or a motorized action to ensure consistent delivery.

- Adjustable Nozzle: Directs the screws to the desired location for assembly, allowing for precise placement in various applications.

- Interfaz de control: Provides operators with the ability to set parameters such as feed rate and dispense timing, enhancing user control and flexibility.

Aplicaciones

- Manufacturing and Assembly Lines: Ideal for various industries such as automotive, electronics, and furniture, where fast and accurate screw fastening is crucial.

- Automated Workstations: Enhances productivity in workstations by providing a steady supply of screws, reducing downtime and manual labor.

- Seguro de calidad: Ensures that screws are delivered in an orderly manner, minimizing errors and improving the overall quality of assembled products.

Conclusión

The Cylinder Screw Feed is a vital component for modern production systems, designed to optimize the efficiency of screw dispensing in assembly processes. Its automated features, durability, and adaptability make it an essential tool for manufacturers seeking to improve productivity and maintain high standards of quality in their operations.