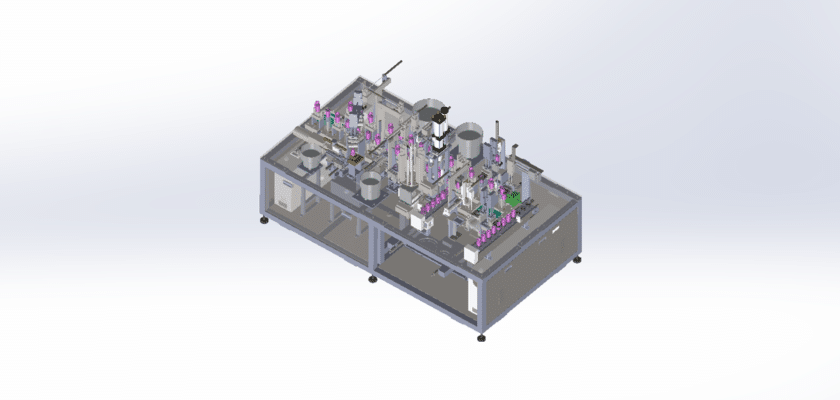

Este dibujo detallado de la línea de ensamblaje de motores de CC ilustra un sistema especializado diseñado para el ensamblaje eficiente de motores de corriente continua (CC) utilizados en diversas aplicaciones, como la automoción, la robótica y la electrónica de consumo. Ideal para fabricantes que buscan aumentar su productividad, esta línea de ensamblaje garantiza resultados de alta calidad a la vez que mantiene la precisión en la fabricación de motores.

Características principales del dibujo:

- Proceso de ensamblaje automatizado:La línea de montaje emplea tecnología de automatización avanzada para agilizar la producción de motores de CC, aumentando significativamente el rendimiento y reduciendo el trabajo manual.

- Manipulación de componentes de alta precisión:Equipado con herramientas de precisión y accesorios para alinear y posicionar componentes, asegurando un ensamblaje preciso que cumple con estrictos estándares de rendimiento.

- Interfaz de control fácil de usar:El panel de control intuitivo permite a los operadores programar y monitorear fácilmente el proceso de ensamblaje, facilitando ajustes rápidos para diferentes diseños y especificaciones de motores.

- Sistemas Integrados de Control de Calidad:Cuenta con estaciones de inspección integradas en puntos críticos para verificar que cada motor ensamblado cumpla con los estándares de calidad, minimizando los defectos y mejorando la confiabilidad general.

- Compatibilidad versátilDiseñado para adaptarse a una variedad de tamaños y configuraciones de motores de CC, lo que lo hace adaptable para diversas aplicaciones en múltiples industrias.

- Construcción robusta y duraderaConstruida con materiales de alta calidad, la línea de ensamblaje está diseñada para brindar longevidad y confiabilidad, lo que garantiza un rendimiento óptimo en entornos de producción exigentes.

Este dibujo sirve como referencia esencial para ingenieros y fabricantes que buscan implementar soluciones de ensamblaje efectivas y eficientes para motores de CC en sus líneas de producción.