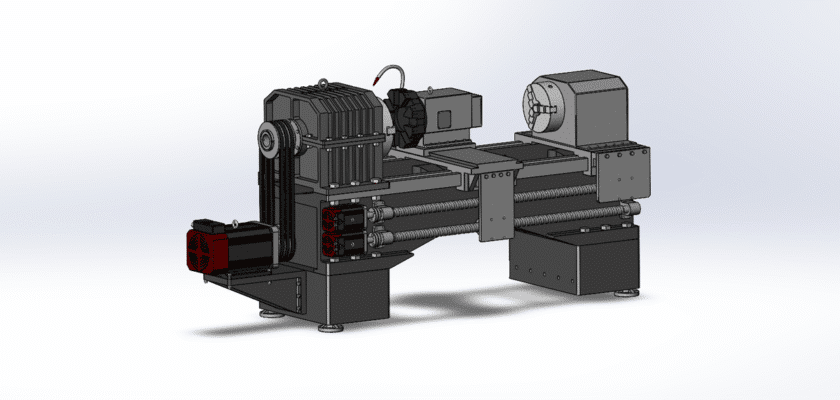

Experimente el poder de la precisión con nuestro exclusivo Torno CNC de doble eje dibujo, disponible para descarga gratuitaEste completo plano técnico ofrece una visión detallada de una máquina versátil diseñada para tornear piezas cilíndricas con una precisión excepcional. Este valioso documento es un recurso esencial para estudiantes, ingenieros y maquinistas que desean comprender los principios básicos del torneado CNC. Detalla la compleja relación entre los dos ejes (el eje Z para el movimiento longitudinal y el eje X para el movimiento radial) que permite la creación de perfiles, conos y roscas complejos. Al estudiar este plano, comprenderá claramente cómo el robusto bastidor, el husillo de alta velocidad y la torreta de herramientas automatizada trabajan juntos para transformar una materia prima en un componente terminado. Este plano es una herramienta educativa perfecta y un recurso valioso para cualquier persona involucrada en el diseño, la fabricación o el mantenimiento de máquinas.

Características principales:

- Bancada de máquina rígida: El dibujo destaca la estructura básica del torno: una bancada robusta que proporciona una estabilidad excepcional. Esta rigidez es crucial para minimizar la vibración y la deflexión durante el corte a alta velocidad, garantizando un acabado superficial superior y tolerancias ajustadas.

- Control de movimiento de doble eje: El plano muestra los ejes X y Z, accionados por husillos de bolas de precisión y servomotores. Este sistema de dos ejes permite que la herramienta de corte se mueva con una precisión increíble, lo que permite crear intrincadas geometrías externas e internas en la pieza de trabajo.

- Torreta de herramientas automatizada: Los planos técnicos ilustran una torreta de herramientas multiestación que indexa automáticamente la herramienta de corte correcta. Esta función automatizada elimina la necesidad de cambios manuales de herramientas, lo que reduce significativamente los tiempos de ciclo y permite la fabricación sin intervención del operador.

- Husillo de alta velocidad: El dibujo ofrece una vista detallada del potente conjunto del husillo. Los rodamientos de precisión y el motor están diseñados para girar la pieza a alta velocidad, lo cual es esencial para una eficiente remoción de material y para lograr una superficie impecable en la pieza final.