Optimize your polymer production with our comprehensive technical documentation for the Extrusion Die Profile PVC. Designing dies for Polyvinyl Chloride (PVC) requires a deep understanding of thermal dynamics and flow rheology to prevent material degradation and ensure dimensional stability. This drawing package provides the intricate engineering data necessary to manufacture high-precision extrusion dies used for window frames, piping, and industrial trim. By utilizing these professional schematics, you can ensure a balanced flow through the die manifold, resulting in a consistent profile thickness and superior surface finish.

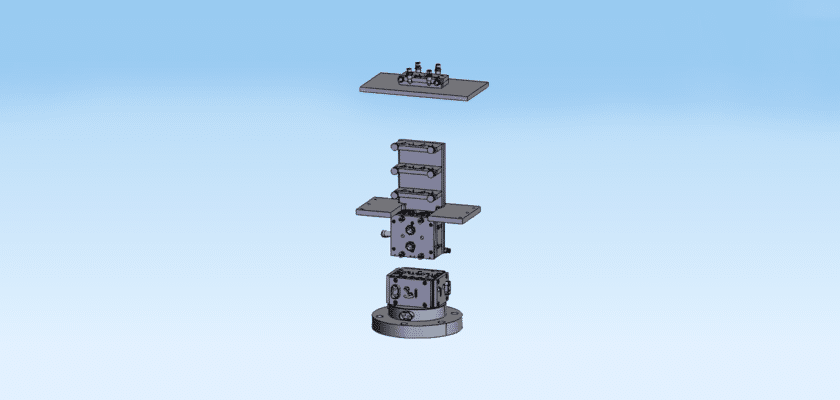

The provided dibujo files offer an exhaustive look at the “land length” and compression ratios required to manage the unique viscosity of PVC. By analyzing the internal mandrel supports and the heater band placement mapped out in these blueprints, engineers can optimize the heat distribution across the die face. We offer these high-fidelity CAD resources for free to help manufacturing teams reduce setup times and eliminate common defects such as surging or uneven cooling.

Our files are ready for immediate integration into your flow simulation software, allowing your team to verify the velocity profile of the melt before the tool is machined. This data-driven approach is essential for achieving the tight tolerances required in the construction and automotive sectors. Download this professional blueprint today to modernize your plastic extrusion workflow and increase your production yield.

Características principales:

- Balanced Flow Manifold: Precision-engineered internal channels designed to ensure uniform material velocity at the die exit.

- Integrated Heating Zones: Detailed layouts for cartridge or band heaters to maintain precise temperature control during the extrusion process.

- Corrosion-Resistant Specification: Designed for construction with high-grade stainless steels to withstand the corrosive nature of PVC melt.

- Optimized Land Length: Calculated geometry to provide sufficient back-pressure for excellent structural density and surface gloss.

- Adjustable Sizing Interface: Features a modular design compatible with various vacuum calibration units and cooling tanks.