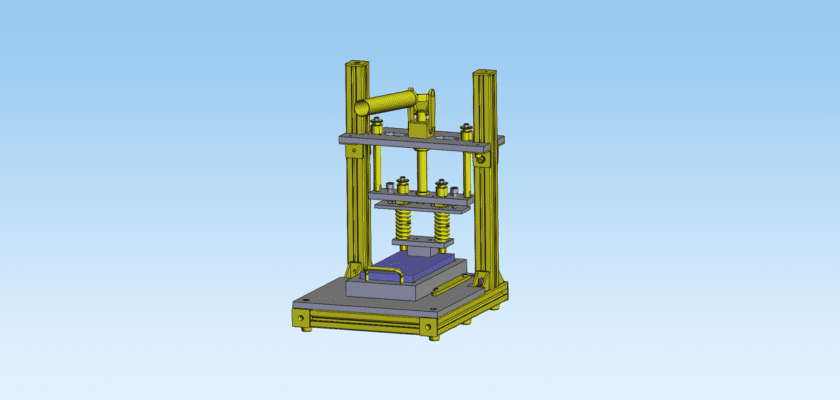

Achieve flawless material handling by choosing to download our professional Film Pressing Clamping Fixture drawing. In manufacturing processes such as vacuum lamination, membrane pressing, or surface coating, maintaining uniform tension and a leak-proof seal on thin films is absolutely critical. This technical drawing provides a detailed mechanical blueprint for a high-performance clamping frame, specifically engineered to hold flexible films securely during high-pressure or high-temperature cycles. It is an essential asset for designers looking to eliminate common defects like film wrinkling, air bubbles, or edge slippage.

By utilizing this comprehensive CAD resource, mechanical engineers can analyze the specialized clamping logic required to distribute force evenly along the perimeter of the film. The drawing includes detailed layouts for the pressure bars and quick-release mechanisms that facilitate rapid workpiece changeover without damaging sensitive materials. Whether you are building a custom press for aerospace composites or a small-scale prototype station for flexible displays, these schematics offer the foundational data needed for structural rigidity and pneumatic integration. Accessing this verified design ensures your production line maintains the high repeatability and tight tolerances required for modern material processing.

Características principales:

- Uniform Perimeter Sealing: A specialized frame design that applies consistent downward pressure to ensure an airtight seal across the entire film surface.

- Anti-Slip Surface Texture: Detailed specifications for the clamping jaw interfaces, featuring micro-textures or rubberized inserts to prevent film migration under tension.

- Thermal Distortion Resistance: Structural insights into the frame’s material composition, designed to remain perfectly flat during high-heat pressing cycles.

- Pneumatic Actuation Layout: Integrated conduit paths for air cylinders, providing synchronized and effortless opening and closing of the clamping jaws.

- Adjustable Tension Control: Includes fine-tuning bolts or spring-loaded guides to accommodate different film elasticities and thicknesses.