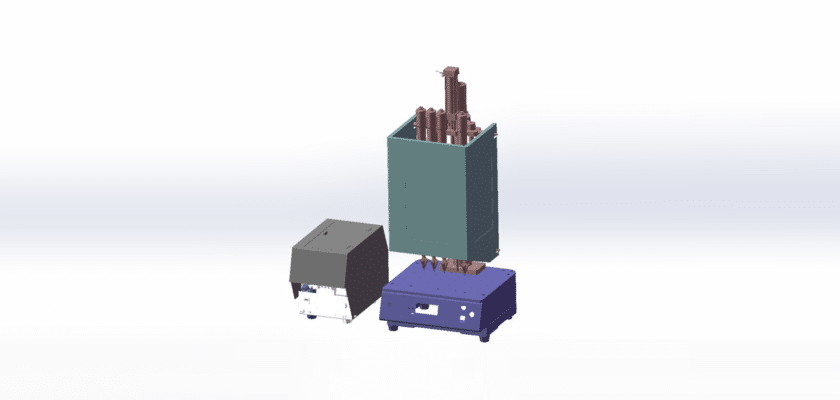

La máquina atornilladora totalmente automática de cuatro ejes es una sofisticada herramienta de ensamblaje diseñada para la fijación de tornillos de alta precisión en diversas aplicaciones industriales. Su avanzada capacidad de movimiento en cuatro ejes permite un acceso versátil a los tornillos en ensamblajes complejos, mejorando significativamente la eficiencia y la precisión de la producción.

Características principales

- Movimiento de cuatro ejes:La máquina está equipada con cuatro ejes de movimiento, lo que le permite alcanzar tornillos ubicados en varios ángulos y ubicaciones, lo que la hace ideal para tareas de ensamblaje complejas.

- Inserción y apriete automatizados de tornillosEl sistema totalmente automatizado agiliza todo el proceso de entrega, inserción y apriete de tornillos, reduciendo el trabajo manual y aumentando el rendimiento.

- Ajustes de par personalizablesLos operadores pueden ajustar fácilmente los niveles de torsión para diferentes tipos de tornillos y materiales, lo que garantiza una fijación óptima sin riesgo de apriete excesivo o daños.

- Interfaz de control intuitiva:Un panel de control digital fácil de usar permite una fácil programación y monitoreo de las operaciones de la máquina, facilitando ajustes rápidos y retroalimentación en tiempo real.

Componentes

- Manipulador multieje:El corazón de la máquina, que proporciona un movimiento preciso de cuatro ejes para acceder a los tornillos desde varios ángulos y posiciones.

- Sistema de alimentación de tornillo:Un mecanismo automatizado que suministra eficientemente tornillos al cabezal de fijación, garantizando un funcionamiento suave y continuo.

- Sistema de control de par:Una unidad sofisticada que gestiona el par aplicado durante el proceso de fijación, garantizando el cumplimiento de los requisitos especificados.

- Marco de base robusto:Una estructura robusta que soporta la máquina, minimizando las vibraciones y mejorando la estabilidad durante la operación.

Aplicaciones

- Fabricación de productos electrónicos:Ideal para ensamblar dispositivos electrónicos delicados donde la colocación precisa de los tornillos y el control del torque son fundamentales.

- Ensamblaje de automóviles:Adecuado para fijar componentes en vehículos, incluidos interiores, motores y chasis, garantizando confiabilidad y durabilidad.

- Producción de bienes de consumo:Eficiente en el montaje de diversos productos, incluidos muebles y electrodomésticos, donde una fijación de alta calidad es esencial.

Conclusión

La máquina atornilladora totalmente automática de cuatro ejes es un recurso invaluable para la fabricación moderna, diseñada para optimizar la eficiencia y la precisión de los procesos de atornillado. Sus capacidades avanzadas, funciones automatizadas y ajustes personalizables la convierten en una herramienta clave para mejorar la productividad y mantener altos estándares de calidad en diversas industrias. Esta máquina ejemplifica los últimos avances en tecnología de automatización, contribuyendo a la optimización de las operaciones y a una mayor fiabilidad del producto.