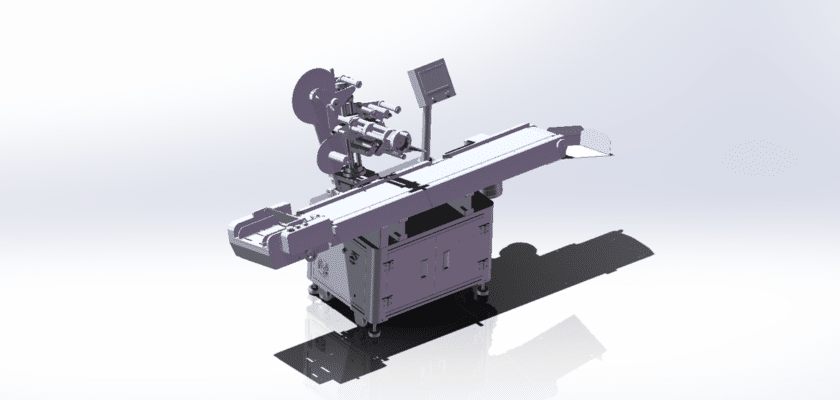

Un dibujo de una máquina de papas fritas totalmente automática es una ilustración técnica que describe el diseño y la funcionalidad de una máquina diseñada específicamente para la producción automatizada de papas fritas, como papas fritas o snacks. Este tipo de máquina es crucial en la industria alimentaria, ya que garantiza una producción eficiente y consistente.

Características principales:

- Disposición general:Una vista detallada de la estructura de la máquina, que muestra la disposición de los componentes y sus interacciones a lo largo del proceso de producción de chips.

- Sistema de alimentación de materia prima:Diagramas que ilustran los mecanismos que suministran materias primas (por ejemplo, patatas u otros ingredientes) a la máquina, incluidos transportadores, tolvas o alimentadores automáticos para un manejo suave.

- Mecanismo de corte:Representación de los sistemas utilizados para cortar materias primas en chips uniformes, con cuchillas ajustables o mecanismos de corte para garantizar la consistencia.

- Unidad para freír o hornear:Información sobre el proceso de cocción, detallando cómo se fríen u hornean las patatas fritas, incluidos los sistemas de control de temperatura y los mecanismos de circulación de aceite para una cocción uniforme.

- Aplicación de condimentos:Detalles sobre los sistemas que aplican condimentos o saborizantes a los chips, que pueden incluir sistemas de aspersión o tumblers para una distribución uniforme.

- Sistema de enfriamiento:Información sobre cómo se enfrían las patatas fritas después de cocinarlas, lo que puede implicar refrigeración por aire o sistemas transportadores para evitar la retención de humedad.

- Unidad de embalaje:Ilustraciones del mecanismo de envasado final, que muestran cómo se dividen las patatas fritas y se sellan en bolsas o contenedores para su distribución.

- Panel de control:Una unidad de control central que administra el funcionamiento de la máquina, permitiendo a los operadores monitorear procesos, ajustar configuraciones y acceder a datos de rendimiento en tiempo real.

- Interfaz de usuario:Detalles sobre la pantalla táctil o el panel de control que proporciona a los operadores acceso intuitivo a las configuraciones de la máquina, incluida la velocidad de producción, el tiempo de cocción y los niveles de condimento.

- Sistemas de control de calidad:Diagramas que muestran sensores o cámaras integrados que monitorean el proceso de producción para garantizar la calidad, asegurando que cada lote cumpla con las especificaciones.

- Sistemas de salida de datos:Información sobre cómo se registran y comunican los datos de producción, incluidos los recuentos de salida y las métricas de calidad, con pantallas digitales para una retroalimentación inmediata.

- Marco mecánico:Detalles sobre los componentes estructurales que soportan la máquina, garantizando estabilidad y durabilidad durante la operación.

- Características de seguridad:Información sobre mecanismos de seguridad, como paradas de emergencia, protectores de seguridad y sensores para garantizar un funcionamiento seguro durante todo el proceso de producción.

- Fuente de alimentación:Información sobre los requisitos eléctricos y sistemas de respaldo para garantizar un funcionamiento confiable.

Este dibujo sirve como referencia integral para ingenieros y técnicos involucrados en el diseño, ensamblaje y mantenimiento de máquinas de chips totalmente automáticas, garantizando altos estándares de eficiencia, precisión y efectividad operativa en los procesos de producción de chips.