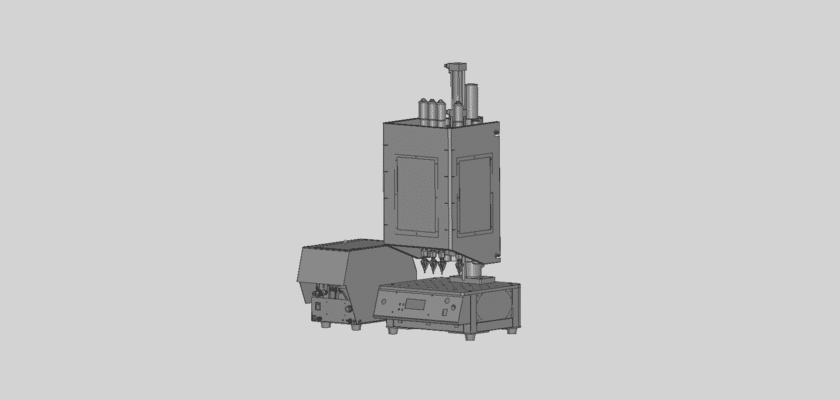

La máquina atornilladora totalmente automática es una solución de ensamblaje avanzada diseñada para automatizar el proceso de atornillado en diversos entornos de fabricación. Esta máquina mejora la productividad al entregar y apretar tornillos de forma eficiente y precisa, lo que la hace ideal para líneas de producción de gran volumen.

Características principales

- Funcionamiento totalmente automatizado: Agiliza todo el proceso de atornillado, desde la alimentación hasta el apriete, minimizando la intervención manual y maximizando la eficiencia.

- Control de par de alta precisión:Equipado con ajustes de torque para garantizar que los tornillos estén apretados según las especificaciones exactas requeridas, evitando daños por apriete excesivo.

- Compatibilidad versátilDiseñado para manejar una amplia gama de tamaños y tipos de tornillos, lo que permite flexibilidad en diversas aplicaciones en múltiples industrias.

- Interfaz fácil de usar:Cuenta con un panel de control digital intuitivo que permite a los operadores programar, monitorear y ajustar fácilmente las operaciones de la máquina en tiempo real.

Componentes

- Sistema de alimentación de tornillo:Un mecanismo automatizado que suministra continuamente tornillos a la unidad de accionamiento, garantizando un flujo de trabajo ininterrumpido.

- Herramienta de conducción:Un destornillador de alto torque que fija tornillos de forma segura, capaz de ajustarse a diferentes tamaños y materiales para una mayor versatilidad.

- Sistema de control:Una unidad basada en PLC que gestiona toda la operación, proporcionando diagnósticos y permitiendo un control preciso sobre el proceso de fijación.

- Marco de base estable:Una estructura robusta que soporta la máquina, reduciendo las vibraciones y asegurando la estabilidad durante el funcionamiento.

Aplicaciones

- Ensamblaje de electrónica:Ideal para fijar tornillos en dispositivos electrónicos complejos, donde la precisión y el cuidado son esenciales.

- Fabricación de automóviles:Adecuado para diversos componentes en vehículos, garantizando un montaje confiable y eficiente en líneas de producción.

- Producción de muebles:Atornilla eficientemente los tornillos en el ensamblaje de muebles, lo que contribuye a mejorar la durabilidad y la calidad de los productos terminados.

Conclusión

La máquina atornilladora totalmente automática es una herramienta esencial para la fabricación moderna, diseñada para mejorar la eficiencia y la precisión en los procesos de atornillado. Sus funciones automatizadas, su diseño robusto y su alta precisión la convierten en un recurso invaluable para los fabricantes que buscan aumentar la productividad y mantener altos estándares de calidad. Esta máquina ejemplifica los últimos avances en tecnología de automatización, contribuyendo a la optimización de las operaciones y a una mayor fiabilidad de los productos en diversas industrias.