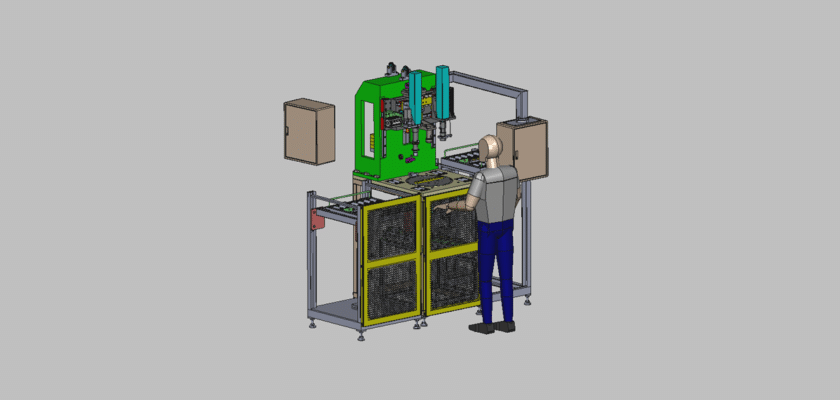

The Fully Automatic Screw Locking Machine is a sophisticated assembly tool designed to streamline the screw fastening process in various manufacturing settings. This machine automates the entire locking operation, ensuring high efficiency and precision, making it ideal for high-volume production environments.

Características principales

- Automatización completa: The machine automates the entire screw locking process, from feeding screws to tightening, significantly reducing manual labor and increasing productivity.

- Control de par de alta precisión: Equipped with advanced torque settings, the machine ensures screws are tightened to the exact specifications required, preventing over-tightening and enhancing product reliability.

- Compatibilidad versátil: Designed to accommodate a wide range of screw sizes and types, making it suitable for diverse applications across multiple industries.

- Interfaz de control fácil de usar: Features an intuitive digital control panel that allows operators to easily set parameters, monitor operations, and make quick adjustments as needed.

Componentes

- Sistema de alimentación de tornillo: An automated mechanism that supplies screws to the locking head, ensuring a continuous flow and minimizing downtime.

- Cabezal de bloqueo: A precision tool that grips and securely tightens screws, designed to handle various sizes and materials.

- Sistema de control: A PLC-based unit that manages the machine’s operations, providing real-time feedback and diagnostics to optimize performance.

- Marco de base estable: A robust structure that supports the machine, reducing vibrations during operation and enhancing overall reliability.

Aplicaciones

- Líneas de montaje de fabricación: Ideal for industries such as electronics, automotive, and appliances, where efficient and reliable screw fastening is crucial.

- Seguro de calidad: Ensures that all screws are fastened to the correct specifications, improving the integrity and safety of assembled products.

- Flexible Production: Suitable for various applications, allowing manufacturers to quickly adapt to changing production needs without sacrificing quality.

Conclusión

The Fully Automatic Screw Locking Machine is an essential tool for modern manufacturing, designed to optimize efficiency and precision in screw fastening processes. Its automated features, high precision, and user-friendly design make it a valuable asset for manufacturers seeking to enhance productivity and maintain high-quality standards. This machine represents a significant advancement in assembly technology, contributing to streamlined operations and improved product reliability across diverse industries.