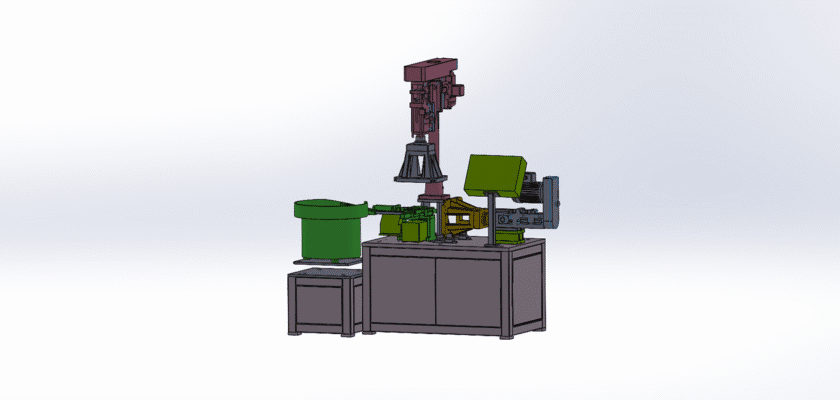

Optimice su proceso de trabajo de metales con nuestro Dibujo gratuito de máquina roscadora totalmente automáticaEste detallado archivo CAD es un recurso esencial para ingenieros, maquinistas y fabricantes de las industrias automotriz, aeroespacial y de maquinaria general. El dibujo ofrece una visión completa de una máquina especializada diseñada para cortar automáticamente roscas internas de tornillo en una pieza con precisión y velocidad excepcionales. Al automatizar este paso crucial, puede garantizar una calidad uniforme de la rosca y aumentar significativamente la productividad.

El plano destaca los complejos mecanismos de la máquina, incluyendo el sistema de alimentación automatizado, el husillo de roscado con control de precisión y el dispositivo de sujeción que sujeta la pieza con seguridad. Comprender estos componentes es fundamental para lograr una producción de alto volumen con mínimos defectos. El diseño está optimizado para un funcionamiento continuo a alta velocidad y es compatible con una amplia gama de tamaños de pieza y especificaciones de rosca. Tanto si está construyendo una nueva estación de roscado, actualizando equipos existentes o estudiando los principios de la automatización industrial, este plano le proporciona la información técnica necesaria. Es una herramienta perfecta tanto para estudiantes como para profesionales, ya que ofrece una visión detallada del futuro de la metalurgia de alta precisión.

Características principales:

- Golpeteo automatizado: El dibujo detalla una máquina que alimenta, sujeta y rosca piezas automáticamente, lo que es crucial para la producción de alta velocidad.

- Husillo de precisión: Se muestra el diseño del husillo de roscado, que está diseñado para un corte de rosca preciso y repetible.

- Sistema de alimentación integrado: El plano incluye el diseño del sistema automatizado que garantiza un suministro continuo de piezas a la máquina.

- Optimización del flujo de trabajo: Una gran herramienta para comprender cómo optimizar el proceso de roscado y mejorar la eficiencia.

- Especificaciones técnicas: Incluye dimensiones y especificaciones críticas para los componentes de la máquina, lo que la hace adecuada para fines de diseño y referencia.