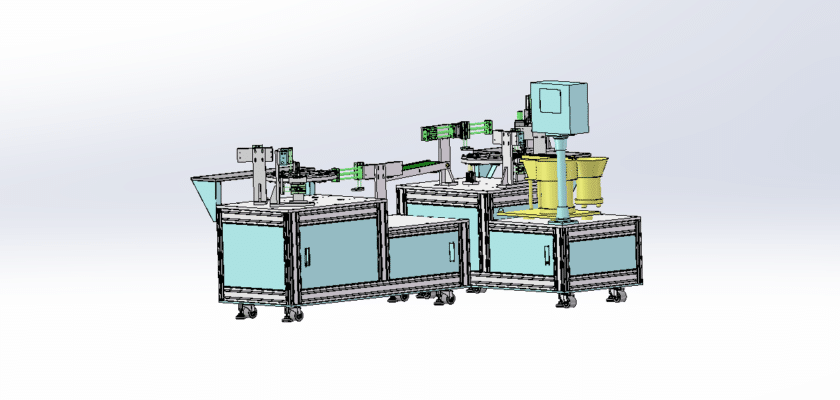

Este dibujo detallado de la máquina ensambladora de plataforma giratoria totalmente automática ilustra un sistema sofisticado diseñado para el ensamblaje automatizado de diversos componentes en diversas industrias, como la automotriz, la electrónica y los bienes de consumo. El diseño de la plataforma giratoria mejora la productividad al facilitar un flujo de trabajo fluido y eficiente durante el proceso de ensamblaje.

Características principales del dibujo:

- Proceso de ensamblaje totalmente automatizado:La máquina emplea tecnología de automatización avanzada para agilizar las operaciones de ensamblaje, aumentando significativamente el rendimiento y reduciendo los requisitos de mano de obra manual.

- Mecanismo de plato giratorio:El plato giratorio integrado permite una rotación continua, lo que permite a los operadores trabajar en múltiples estaciones de ensamblaje sin interrupciones, mejorando así la eficiencia y reduciendo los tiempos de ciclo.

- Manipulación de componentes de alta precisiónEquipado con alimentadores de precisión y herramientas de alineación, el sistema garantiza un posicionamiento y ensamblaje preciso de los componentes, cumpliendo estrictos estándares de calidad.

- Interfaz de control fácil de usar:El panel de control intuitivo permite a los operadores programar y monitorear fácilmente los parámetros de ensamblaje, lo que facilita ajustes rápidos para diferentes tipos de productos y especificaciones.

- Compatibilidad versátil de componentesDiseñado para adaptarse a una amplia gama de componentes y conjuntos, lo que lo hace adaptable para diversas aplicaciones en múltiples industrias.

- Funciones de control de calidad integradoLos sistemas de inspección incorporados monitorean continuamente el proceso de ensamblaje, garantizando que cada producto ensamblado cumpla con los estándares de calidad y minimizando los defectos.

- Construcción robusta y duradera:Fabricada con materiales de alta calidad, la máquina está diseñada para durar y ser confiable, lo que garantiza un rendimiento óptimo en entornos de producción de gran volumen.

Este dibujo sirve como referencia esencial para ingenieros y fabricantes que buscan implementar soluciones de ensamblaje efectivas y eficientes utilizando mecanismos de plataforma giratoria en sus líneas de producción.