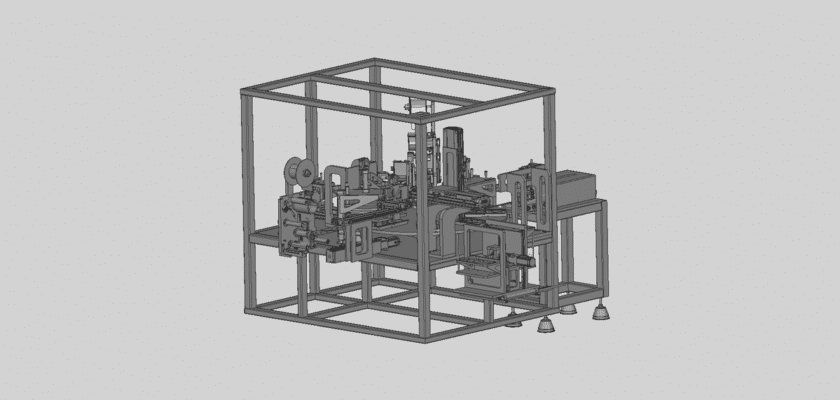

Elevate your material bonding projects to a new level of precision with our free hot-melt film lamination drawing. This professional-grade blueprint details a machine designed for high-precision, double-sided hot-melt film lamination, a crucial process in industries ranging from textiles and automotive to packaging and electronics. This resource provides a comprehensive look at the intricate mechanics, from the heated rollers and tension control systems to the precise application and cooling mechanisms. Whether you’re a student, a DIY enthusiast building a custom machine, or a professional looking for a deeper understanding of the technology, this drawing is an invaluable guide.

Hot-melt lamination is a dry, clean, and highly efficient process that offers superior adhesion and durability. This drawing showcases a design that addresses the common challenges of lamination, such as uneven application, air bubbles, and material wrinkling, by integrating advanced control systems and precise roller mechanics. By studying this blueprint, you can grasp the key principles of thermal bonding and pressure application, enabling you to produce laminated materials with a flawless finish. The double-sided capability further expands the machine’s versatility, allowing for enhanced strength and protection on both sides of a substrate in a single pass. Download this drawing to begin your journey into the world of professional-grade lamination.

Características principales:

- Double-Sided Lamination: The design allows for the simultaneous application of hot-melt film on both sides of a substrate in a single pass, saving time and increasing efficiency while providing a uniform and durable bond.

- Control de temperatura de precisión: The drawing details a system with precise heating elements and sensors to maintain the optimal temperature for melting the adhesive, ensuring a strong and consistent bond without damaging the materials.

- Adjustable Pressure Rollers: The blueprints include a mechanism for adjusting the pressure of the lamination rollers, which is critical for achieving perfect adhesion and a bubble-free finish across different material thicknesses.

- Sistema de control de tensión: This drawing highlights a sophisticated tension control system to ensure that the film and the substrate are fed smoothly and without wrinkles, resulting in a flawless final product.

- Aplicación versátil: The machine design is suitable for a wide range of materials, including textiles, foams, films, and various substrates, making it a versatile tool for multiple industries and applications.