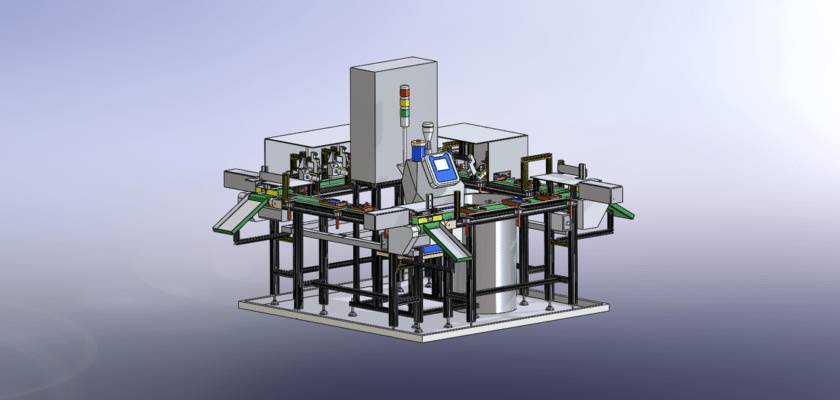

Descargar el dibujo Para el Electronic Manufacturing Hot Melt Glue Spot Welding Production Line, a state-of-the-art system designed for high-precision, high-efficiency glue spot welding in electronic manufacturing. This automated production line is ideal for industries requiring precise bonding of electronic components, offering seamless integration of hot melt glue technology for optimal results.

Características principales:

- Automated Production Line: The line is fully automated, providing smooth integration with existing manufacturing workflows. It ensures consistent quality and high throughput, reducing human error and increasing production efficiency.

- Hot Melt Glue Spot Welding: Designed specifically for the application of hot melt glue in electronic manufacturing, the system offers precise control over the amount and placement of glue, ensuring strong and durable bonds.

- Soldadura de alta precisión: With advanced spot welding technology, the machine guarantees accurate and reliable spot welding for delicate electronic components, ensuring a secure and long-lasting bond.

- Eficiencia energética: This production line is designed with energy-saving features, optimizing power consumption while maintaining high operational performance. It reduces operational costs, making it more environmentally friendly.

- Flexible and Scalable: Capable of handling various types of components and production requirements, this line offers flexibility to meet different production needs. Its modular design makes it easily scalable for future upgrades or increased production volume.

Al descargar el dibujo, manufacturers can gain detailed insights into the machine’s specifications, helping to streamline installation, operation, and maintenance for efficient production.