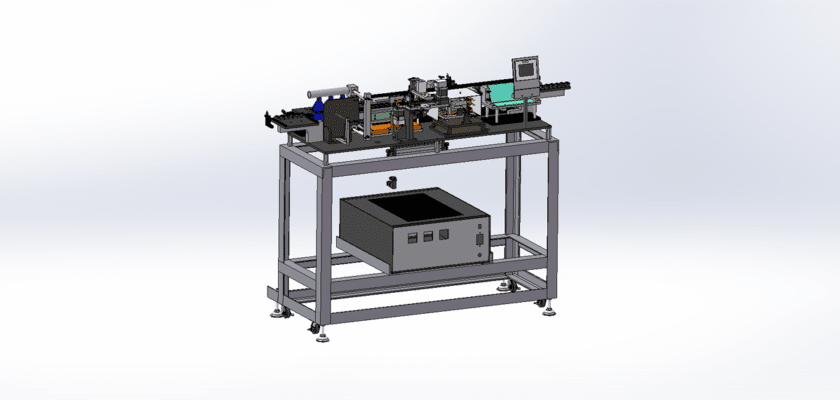

Descargar el dibujo Para el Máquina de soldadura automática de inductoresUna herramienta de vanguardia diseñada para la soldadura eficiente y precisa de inductores en la fabricación electrónica. Esta máquina optimiza el proceso de soldadura, ofreciendo consistencia, velocidad y resultados de alta calidad, ideales para entornos de producción en masa.

Características principales:

- Soldadura de precisión: En Máquina de soldadura automática de inductores Utiliza automatización avanzada para proporcionar una soldadura precisa a los inductores con mínimo riesgo de errores. El sistema garantiza una aplicación uniforme de la soldadura, evitando uniones frías y asegurando conexiones eléctricas robustas.

- Operación de alta velocidad: Diseñada para una producción de gran volumen, esta máquina trabaja a velocidades más rápidas que los métodos tradicionales de soldadura manual, lo que aumenta el rendimiento y reduce significativamente el tiempo del ciclo sin comprometer la calidad.

- Control automático de procesos: La automatización de la máquina garantiza una mínima intervención manual, lo que reduce los errores del operador y la posibilidad de defectos. El proceso de soldadura se supervisa y ajusta en tiempo real para obtener resultados óptimos.

- Aplicaciones versátiles: Aunque está diseñada principalmente para la soldadura de inductores, esta máquina se puede adaptar para su uso en una variedad de otros componentes que requieren soldadura automatizada, incluidas resistencias, condensadores y otros elementos de placas de circuito.

- Diseño energéticamente eficiente: En Máquina de soldadura automática de inductores Está diseñado pensando en la eficiencia energética, minimizando el consumo de energía durante su funcionamiento. Esto reduce los costos operativos generales, manteniendo un alto rendimiento y productividad.

Esta máquina es una herramienta esencial para las líneas de montaje electrónico modernas, mejorando la productividad y garantizando los más altos estándares de soldadura.