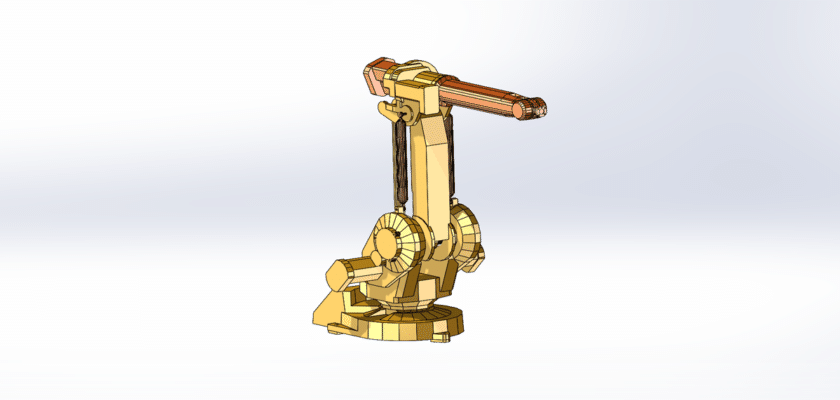

An IRB 1400 Welding Robot Arm Drawing is a detailed technical illustration that depicts the design, components, and functionality of the ABB IRB 1400 robotic arm, specifically tailored for welding applications. This drawing is essential for engineers, technicians, and operators involved in the setup, operation, and maintenance of this industrial robot.

Características principales:

- Overall Layout: A comprehensive view of the IRB 1400 robot arm, showcasing its structure and the arrangement of its components in a welding setup.

- Arm Structure: Detailed illustrations of the robot’s frame, including:

- Links and Joints: Information about the individual segments (links) of the arm and the types of joints (revolute) that allow for flexible movement.

- Degrees of Freedom: Specifications on the six degrees of freedom that enable the arm to reach a wide range of positions and orientations for precise welding.

- End Effector: Descriptions of the welding torch or tool attached to the end of the arm, including:

- Welding Torch Design: Details on the torch used for MIG, TIG, or arc welding, highlighting its features for optimal performance.

- Cable Management: Information on how the cables for power and control are routed to prevent tangling during operation.

- Control System: Details about the control unit that manages the robot’s operations, including:

- Robot Controller: Information on the ABB controller used for programming and controlling the welding processes.

- User Interface: Illustrations of control panels or software interfaces that allow operators to program welding paths and monitor performance.

- Sensors and Feedback Systems: Diagrams showing integrated sensors that monitor the robot’s position, the quality of the weld, and other critical parameters to ensure accurate operation.

- Base and Stability: Information about the base of the IRB 1400, which provides a solid foundation and may include options for mounting on different surfaces.

- Safety Features: Information on safety mechanisms, including emergency stop buttons, protective enclosures, and safety interlocks designed to ensure safe operation during welding tasks.

- Maintenance Access Points: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the robotic arm.

- Performance Specifications: Summary of key performance metrics, such as payload capacity, reach, speed, and precision, providing essential information for operational planning.

- Application Context: Brief descriptions of typical applications for the IRB 1400 welding robot arm, such as in automotive manufacturing, metal fabrication, and assembly processes.

This drawing serves as a crucial reference for anyone involved in the operation and maintenance of the IRB 1400 welding robot arm, ensuring effective performance, reliability, and adherence to industry standards in various welding applications.