Achieve precise volumetric control with our professional Liquid Level Detection Tank drawing. In industries ranging from food and beverage to petrochemicals, inaccurate level readings can lead to pump cavitation, tank overflows, or interrupted production cycles. This technical CAD resource provides a comprehensive blueprint for a specialized process vessel optimized for high-accuracy level sensing. By downloading this file from MechStream, you gain access to a design that addresses common sensing challenges such as surface turbulence, foam interference, and “dead zones.”

The design featured in this package focuses on Measurement Stability. The drawing includes detailed layouts for an internal Stilling Well (or bypass chamber) which isolates the sensor from the main tank’s agitation, ensuring a “clean” surface for ultrasonic or radar waves. By utilizing this blueprint, you can implement a multi-redundant sensing strategy, combining non-contact top-down sensors with side-mounted hydrostatic pressure transducers or capacitive probes. This is an essential asset for designers of buffer tanks, cooling towers, and hazardous chemical storage.

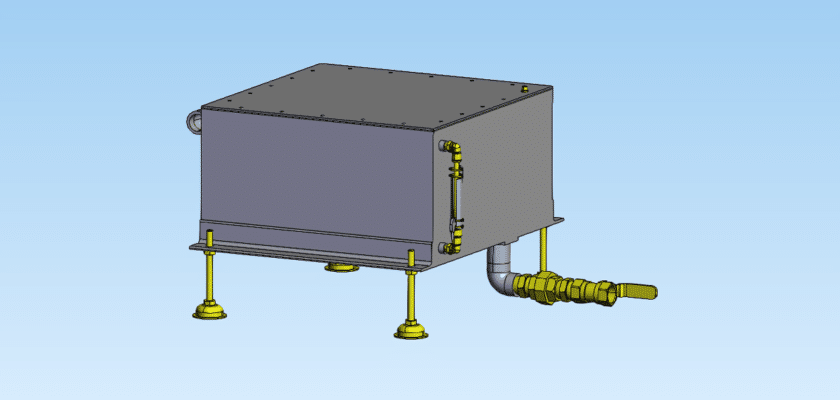

Our technical documentation prioritizes accuracy and maintenance access. The assembly features sloped bottoms for complete drainage and specialized “sight glass” ports for manual visual verification. Whether you are building a pilot-scale bioreactor or a massive municipal gray-water tank, this drawing provides the exact flange dimensions, sensor-to-liquid clearance requirements, and material compatibility specs needed for a professional-grade monitoring installation.

Características principales:

- Anti-Turbulence Stilling Well: Engineered to provide a calm fluid surface for ultra-precise readings in agitated or boiling liquids.

- Multi-Sensor Port Configuration: Includes pre-defined NPT or Flange mounts for ultrasonic, radar, and vibrating fork (point-level) sensors.

- Internal Baffle System: Designed to prevent “sloshing” and signal scattering in mobile or high-flow applications.

- Hydrostatic Pressure Port: Features a recessed bottom-mount port for pressure-based level transmitters, protected from sediment buildup.

- Vented Atmospheric Design: Includes a filtered breather assembly to ensure internal pressure remains equal to ambient, preventing sensor drift.