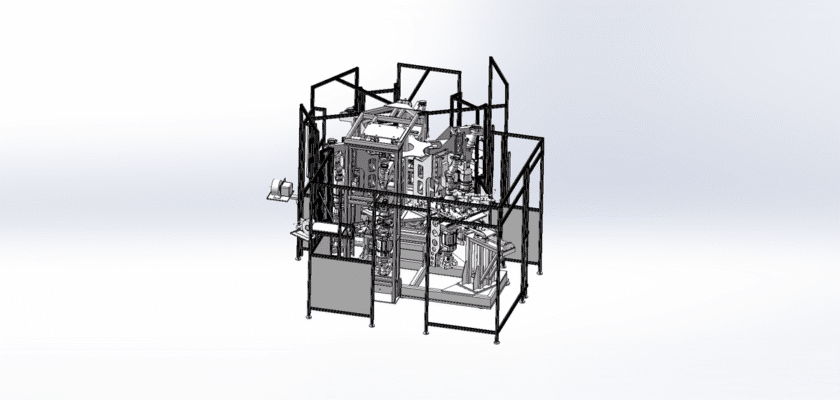

Los equipos de automatización no estándar de combinación multiestación son sistemas de maquinaria altamente especializados y personalizados, diseñados para realizar una serie de tareas complejas y secuenciales en un único proceso integrado. A diferencia de la automatización estándar, este tipo de equipo se construye desde cero para satisfacer las necesidades únicas y específicas de la línea de producción de una empresa, desde la alimentación y el ensamblaje automáticos hasta las pruebas y el empaquetado. Es la clave para lograr un alto grado de eficiencia y consistencia en la producción donde las soluciones estándar no son suficientes. Al combinar múltiples estaciones de trabajo, estos equipos reducen la mano de obra, minimizan la manipulación de materiales y acortan drásticamente los ciclos de producción.

Este conjunto de dibujos descargable gratuito ofrece una perspectiva excepcional y valiosa del diseño de un sistema tan sofisticado. Ofrece una visión completa de los sistemas de control mecánico, neumático y electrónico que trabajan en armonía para automatizar procesos complejos. Este dibujo es una excelente herramienta educativa para estudiantes, una referencia de diseño para ingenieros y una fuente de inspiración para quienes buscan comprender la cumbre de la fabricación moderna.

Características principales:

- Diseño modular y flexible: Los dibujos ilustran cómo diferentes estaciones, como brazos robóticos, alimentadores y transportadores, se integran en una unidad cohesiva, lo que permite una fácil reconfiguración para diferentes tipos de productos.

- Sistema de Control Integrado: El plan detalla la compleja interacción de PLC, sensores y actuadores que controlan con precisión cada paso del proceso automatizado, garantizando una alta repetibilidad y errores mínimos.

- Personalizado para tareas específicas: El dibujo proporciona un ejemplo real de cómo se puede adaptar una máquina a un flujo de producción único, demostrando los principios de la automatización no estándar.

- Flujo de trabajo de alta eficiencia: El diseño resalta una ruta de producción optimizada que mueve una pieza de trabajo a través de múltiples operaciones sin interrupciones, lo que aumenta significativamente el rendimiento y reduce los costos laborales.