Integrating a needle-type (dot peen) marking system into a production line presents serious challenges. These markers are incredibly loud, require perfectly stable part-holding, and the high-speed marking pin poses a safety risk to operators. Building a custom enclosure that solves all these issues is a difficult engineering task, and commercial-grade cabinets are extremely expensive.

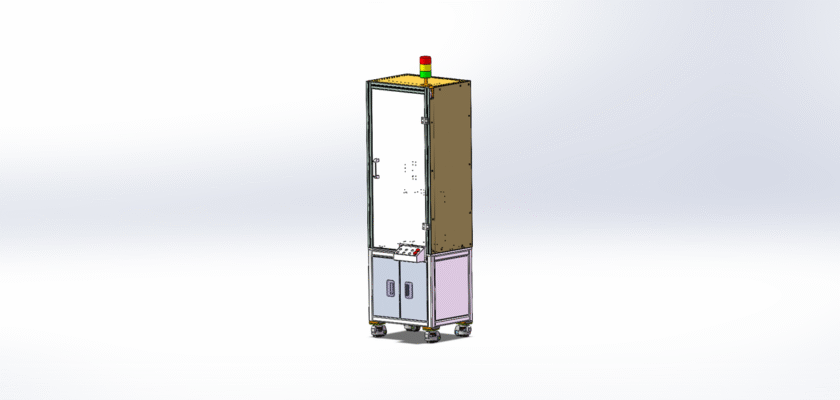

MechStream now offers the complete Needle-Type Marking Cabinet drawing. This is a professional blueprint for a benchtop, sound-dampened safety enclosure. It’s designed to house a standard dot peen or pin marking head, transforming your setup into a safe, quiet, and efficient “Class 1” marking station.

Our design is fabrication-ready. It includes a robust steel body with provisions for acoustic foam, an operator viewing window, and a safety-interlocked door. Crucially, the plan details an adjustable internal mounting gantry for the marking head and a heavy-duty T-slot plate base. This T-slot base is essential for securely mounting jigs and fixtures, ensuring every part is marked with perfect, repeatable precision.

Stop dealing with noise complaints and makeshift setups. Download our free CAD and PDF files today to build a professional marking cabinet that protects your staff and improves your part quality.

Características principales:

- Sound-Dampened Design: Engineered for a sealed body and internal acoustic foam, dramatically reducing the high-frequency noise of dot peen marking.

- T-Slot Fixturing Base: Includes the drawing for a heavy-duty T-slot base plate, allowing for modular and rigid clamping of parts.

- Adjustable Head Mount: Features an internal gantry or arm to securely mount and adjust the position of the dot peen marking head.

- Operator Safety: The plan includes a safety-interlocked door and a protective viewing window (spec’d for polycarbonate) to ensure safe operation.

- Integrated Services: Designed with cutouts for lighting, power entry, and a compressed air connection for the marking pin.