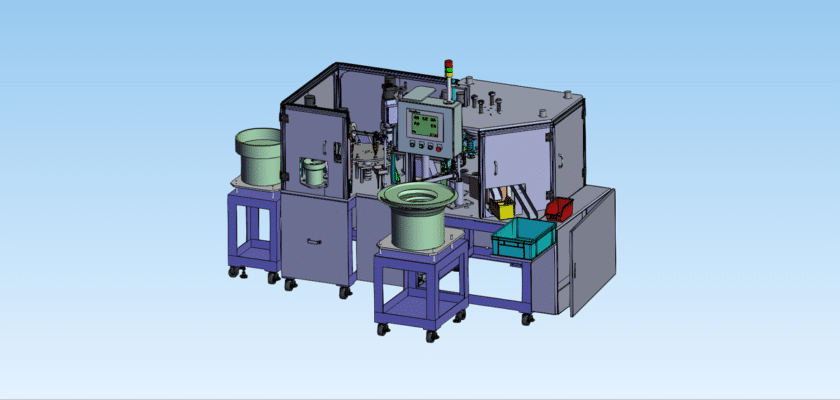

Ensure superior weld purity and structural strength with our exclusive, free drawing package Para el Protector Welding Machine! Specifically designed for Gas Metal Arc Welding (GMAW/MIG) and other shielded processes, this machine is absolutely essential for protecting the molten weld pool from atmospheric contaminants like nitrogen and oxygen. By integrating a precise gas delivery system with a stable power source, the protector welder delivers clean, high-quality beads with minimal oxidation, making it a staple in automotive manufacturing, shipyard construction, and heavy steel fabrication.

Este comprehensive technical drawing set provides the detailed blueprints for constructing a professional-grade shielded welding system. The plans detail the robust inverter power source housing, the integrated gas solenoid and regulator mounting, the specialized wire feed assembly, and the cooling architecture required for high-duty cycle operations. Welding engineers, machine designers, industrial fabricators, and maintenance professionals will find these accurate, industry-standard drawings invaluable for building, troubleshooting, or customizing their protective welding equipment. Stop dealing with porous welds and weak joints. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and highly effective protector welding machine. Secure your free welder drawing now and achieve flawless metal fusion!

Características principales:

- Gas Flow Control System: Detailed blueprints of the integrated solenoid valves, gas line routing, and regulator interfaces designed for precise shielding gas delivery.

- Stable Inverter Power Source: Schematics illustrating the internal electronic component layout for consistent arc voltage and current control.

- Precision Wire Feeder: Drawings detailing the motorized drive roll assembly and tensioning system for smooth, birdnest-free wire delivery to the torch.

- Sistema de gestión térmica: Blueprints specifying the fan placement, heat sink geometry, and airflow pathways to ensure reliable performance under heavy workloads.

- Ergonomic Chassis and Mobility: Details on the reinforced steel enclosure, including mounting points for gas cylinders and heavy-duty casters for workshop mobility.