Achieve high-power linear translation with our professional Lifting Mechanism Using Rack and Pinion drawing. When belt-driven or lead-screw systems lack the rigidity or speed required for heavy vertical lifts, the rack and pinion is the industry standard. This technical CAD resource provides a comprehensive blueprint for a vertical lifting stage designed to convert rotary torque directly into powerful, stable upward force. By downloading this file, you gain access to a design capable of handling significant payloads with high efficiency and no risk of “stretch” or mechanical backlash.

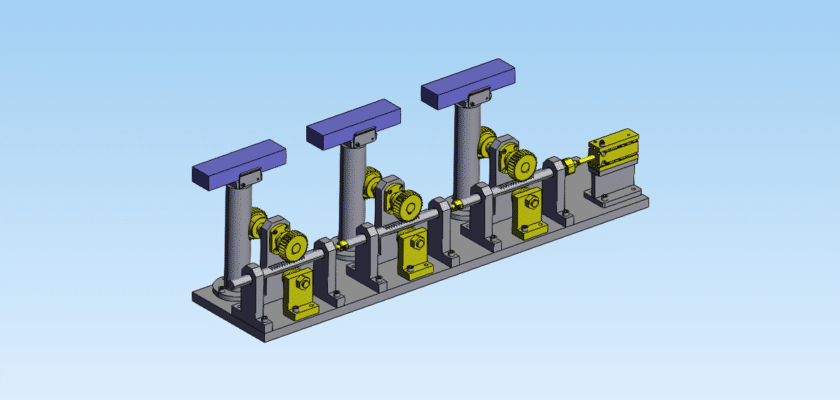

The design featured in this package focuses on the integration of high-precision gear racks and matching pinions. The drawing includes detailed views of the guiding system—utilizing heavy-duty linear rails or V-groove rollers—to ensure the rack remains perfectly meshed with the drive gear throughout the entire stroke. By utilizing this blueprint from MechStream, you can implement a lifting solution ideal for automated storage and retrieval systems (ASRS), adjustable workbenches, and heavy-duty robotic lift stations.

Our technical documentation prioritizes safety and mechanical longevity. The assembly features integrated fail-safe brakes and mechanical end-stops to prevent the load from dropping in the event of a power loss. Whether you are building a custom freight lift or a precision theater stage lift, this drawing provides the exact gear modules ($m$), pressure angles, and mounting tolerances required to ensure smooth, quiet, and reliable operation under heavy industrial loads.

Características principales:

- Unlimited Stroke Potential: Unlike cylinders or lead screws, the lifting height can be extended simply by adding more rack segments.

- Zero-Slip Positive Drive: Ensures 100% mechanical engagement, making it ideal for synchronized lifts where multiple units must move together.

- Alta eficiencia: Provides superior power transmission with minimal energy loss compared to high-friction worm gears or screw drives.

- Rigid Structural Support: Designed with reinforced mounting plates to handle high radial and axial loads during the lifting cycle.

- Maintenance-Friendly Design: Features open access for lubrication and easy adjustment of the pinion-to-rack backlash.