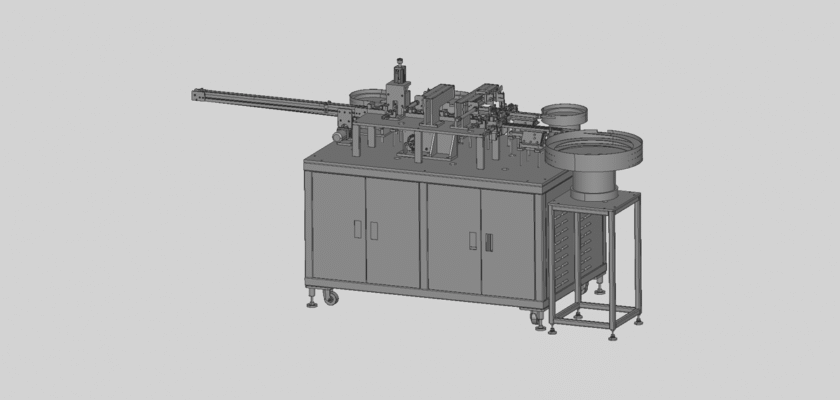

A máquina de montaje automático de relés Es una solución de vanguardia para la fabricación de relés eléctricos en grandes volúmenes. Este sofisticado equipo automatiza cada paso del proceso de ensamblaje, desde la alimentación de componentes y su colocación precisa hasta la soldadura y las pruebas finales. Al eliminar la mano de obra, estas máquinas aumentan significativamente la velocidad de producción, mejoran la consistencia del producto y garantizan un alto nivel de control de calidad. El plano detallado, disponible para descarga gratuita, proporciona un plano completo de un sistema de ensamblaje de relés de calidad profesional. Es un recurso invaluable para ingenieros mecánicos y eléctricos, técnicos y cualquier persona interesada en la automatización industrial. El estudio de este plano le brindará una comprensión profunda de los sistemas mecánicos, neumáticos y eléctricos que funcionan en perfecta sincronía para construir relés confiables y precisos. Este es un documento esencial para diseñar una nueva línea de producción, modernizar maquinaria existente o simplemente con fines educativos.

Características principales:

- Automatización de alta velocidad: Diseñado para ciclos de ensamblaje rápidos y continuos para satisfacer las demandas de producción de productos electrónicos de alto volumen, reduciendo drásticamente los tiempos de ciclo y aumentando la producción.

- Colocación precisa de componentes: Utiliza sistemas robóticos y de visión avanzados para garantizar el manejo y la instalación precisos incluso de los componentes más pequeños, minimizando errores y garantizando la calidad del producto.

- Control de Calidad Integrado: Cuenta con sofisticados sistemas de inspección con sensores y cámaras que detectan y rechazan automáticamente piezas defectuosas o relés incorrectamente ensamblados, garantizando productos consistentes y confiables.

- Diseño modular y flexible: El diseño de la máquina es modular, lo que permite una fácil personalización, mantenimiento y adaptabilidad para ensamblar varios tipos de relés con diferentes tamaños y especificaciones.