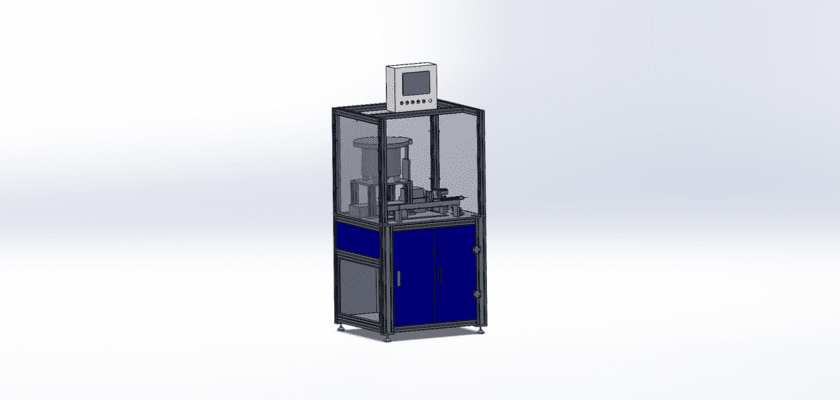

Optimice su línea de producción y elimine errores de ensamblaje manual con nuestro plano técnico gratuito para una máquina de carga automática de anillos de goma. Este plano completo es un recurso esencial para ingenieros, estudiantes y fabricantes que buscan mejorar la eficiencia y la precisión. La manipulación manual de anillos de caucho puede ser lenta, imprecisa y propensa a errores humanos, lo que genera defectos costosos y cuellos de botella en la producción. Esta máquina está diseñada por expertos para superar estos desafíos, garantizando la alimentación y colocación rápida y precisa de anillos de goma en varios componentes. Descargue el plano hoy mismo y dé el primer paso hacia un proceso de fabricación más eficiente, fiable y rentable. Este documento detallado proporciona todos los esquemas y dimensiones necesarios para comprender la mecánica y la funcionalidad básicas, permitiéndole construir o adaptar el diseño a sus necesidades específicas.

Características principales:

- Operación de alta velocidad: La máquina está diseñada para un alto rendimiento, lo que aumenta significativamente la velocidad de producción y reduce el tiempo dedicado al trabajo manual.

- Precisión y exactitud: Equipada con sistemas de control avanzados, la máquina garantiza una alineación y colocación precisa de cada anillo de goma, minimizando el riesgo de daños o mal montaje.

- Diseño versátil: Su diseño flexible le permite manipular una amplia gama de tamaños y tipos de anillos de goma, lo que lo hace adecuado para diversas industrias, incluidas la automotriz, la plomería y la electrónica.

- Costos laborales reducidos: Al automatizar el proceso de carga, esta máquina reduce la necesidad de intervención manual, lo que le permite reasignar mano de obra calificada a tareas más complejas.

- Construcción duradera: El diseño utiliza materiales robustos, garantizando confiabilidad y rendimiento duraderos incluso en entornos industriales exigentes.