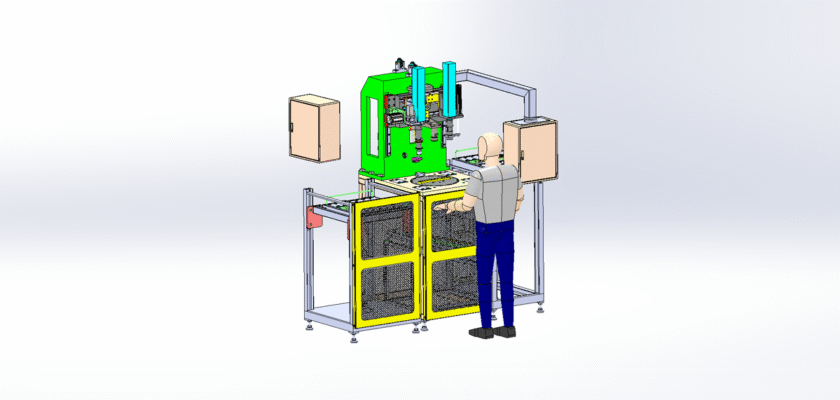

Una máquina de apriete de tornillos es una herramienta indispensable en la fabricación moderna, garantizando precisión y consistencia En el proceso de ensamblaje. Esta máquina, también conocida como atornilladora o fijadora de tornillos, automatiza la tediosa y repetitiva tarea de apretar tornillos, eliminando así el error humano y aumentando significativamente la eficiencia de la producción. Es un componente crítico en diversas industrias, desde la electrónica y los electrodomésticos hasta la automoción y la robótica. Nuestra dibujo CAD gratuito Proporciona una visión detallada de la mecánica de un sistema de apriete de tornillos, ofreciendo un recurso valioso para ingenieros, estudiantes y entusiastas del bricolaje que buscan comprender, diseñar u optimizar sus propias soluciones de ensamblaje automatizado.

La función principal de esta máquina es garantizar que cada tornillo se apriete con el par y el ángulo correctos, evitando tanto el apriete excesivo (que puede dañar la pieza o el tornillo) como el insuficiente (que puede provocar fallos en el producto). Mediante un proceso controlado y automatizado, se logra un nivel de precisión y repetibilidad imposible de igualar con el trabajo manual. El sistema suele integrarse con un alimentador de tornillos para garantizar un suministro continuo y un brazo robótico o sistema de pórtico para posicionar con precisión el cabezal del destornillador. Esta integración permite una automatización completa, desde la entrega del tornillo hasta el apriete final, lo que la convierte en un componente esencial de las líneas de fabricación de alto volumen.

Características principales:

- Control automatizado y preciso: Garantiza que los tornillos se aprieten según las especificaciones exactas, mejorando la calidad y la confiabilidad del producto.

- Mayor velocidad de producción: Reduce significativamente el tiempo de montaje y aumenta la producción general.

- Ergonómico y seguro: Reduce la fatiga del operador y elimina el riesgo de lesiones por esfuerzo repetitivo asociadas con el ajuste manual.

- Aplicación versátil: Se puede personalizar para una amplia gama de tipos, tamaños y materiales de tornillos.

- Integración perfecta: Diseñado para trabajar con otros sistemas automatizados, como alimentadores de tornillo y brazos robóticos, para una solución de ensamblaje completa.