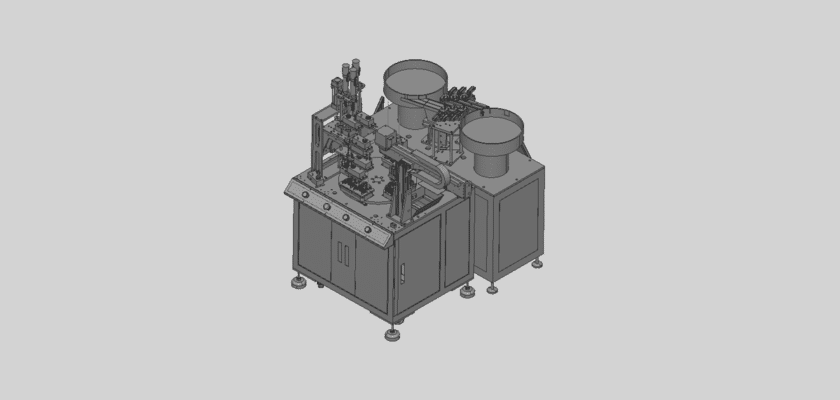

La máquina de bloqueo de tornillos de seis ejes es una solución robótica avanzada diseñada para automatizar el proceso de fijación de tornillos en entornos de ensamblaje complejos. Con su brazo robótico de seis ejes, esta máquina ofrece una flexibilidad y precisión inigualables, lo que le permite alcanzar y bloquear tornillos en diversas posiciones y ángulos, lo que la hace ideal para aplicaciones que requieren movimiento multidimensional. Perfecta para industrias como la automotriz, la electrónica, la aeroespacial y la fabricación de dispositivos médicos, esta máquina garantiza un bloqueo de tornillos de alta velocidad, consistente y fiable con mínima intervención manual.

Características principales:

- Brazo robótico de seis ejes: El brazo robótico de seis ejes permite un movimiento multidireccional, lo que proporciona máxima flexibilidad para aplicaciones de bloqueo de tornillos en espacios complejos o reducidos. Esto permite la colocación y el apriete precisos de tornillos en diversos ángulos y posiciones.

- Operación totalmente automatizada: La máquina de fijación de tornillos de seis ejes automatiza todo el proceso de fijación de tornillos, desde la alimentación hasta la colocación y el apriete. Esto reduce la manipulación manual, aumenta el rendimiento y garantiza resultados consistentes y de alta calidad en cada ciclo de montaje.

- Control de par de alta precisión: Equipada con tecnología avanzada de control de par, la máquina garantiza que cada tornillo se apriete con el par exacto requerido, evitando problemas comunes como el apriete excesivo o insuficiente. Esto da como resultado conjuntos fiables y duraderos.

- Flexible y programable: El sistema ofrece opciones de programación muy flexibles, lo que permite a los usuarios configurar parámetros específicos como el tamaño del tornillo, los valores de torque, la velocidad y el posicionamiento. Esta versatilidad lo hace adecuado para una amplia gama de requisitos y aplicaciones de producción.

- Monitoreo y retroalimentación en tiempo real: La máquina cuenta con sensores avanzados y sistemas de monitorización que proporcionan información en tiempo real sobre el proceso de atornillado. Cualquier error o problema se detecta al instante, garantizando que solo los componentes correctamente ensamblados pasen a la siguiente etapa de producción.

- Rendimiento de alta velocidad: Diseñada para líneas de montaje de alta velocidad, la máquina de bloqueo de tornillos de seis ejes ofrece un rendimiento rápido sin sacrificar la precisión. Su alto rendimiento la hace ideal para industrias con demandas de producción a gran escala.

- Interfaz fácil de usar: El sistema está equipado con una interfaz táctil intuitiva que facilita su configuración y operación. Los operadores pueden supervisar todo el proceso, ajustar la configuración y garantizar un rendimiento óptimo de la máquina con el mínimo esfuerzo.

- Durable y de bajo mantenimiento: Fabricada con materiales de alta calidad, la máquina de bloqueo de tornillos de seis ejes está diseñada para un rendimiento duradero y fiable en entornos industriales exigentes. Su diseño de bajo mantenimiento ayuda a minimizar el tiempo de inactividad y los costes de mantenimiento.

- Características de seguridad: La máquina incluye múltiples funciones de seguridad, como botones de parada de emergencia, sensores de movimiento y cubiertas protectoras, lo que garantiza un entorno de trabajo seguro para los operadores. Estas características ayudan a prevenir accidentes durante la operación.

- Eficiencia energética: Diseñada con tecnología de ahorro de energía, la máquina funciona de manera eficiente, lo que ayuda a reducir el consumo de energía y disminuir los costos operativos.

Aplicaciones:

- Fabricación de automóviles: Ideal para fijar tornillos en el ensamblaje de automóviles, incluidas piezas de motor, sistemas eléctricos y componentes de la carrocería, donde la precisión y la eficiencia son cruciales.

- Ensamblaje de electrónica: Perfecto para la fijación automatizada de tornillos en el ensamblaje de dispositivos electrónicos como teléfonos inteligentes, computadoras, televisores y placas de circuitos, donde los componentes pequeños requieren un manejo preciso.

- Fabricación aeroespacial: Esencial para la fijación de tornillos de alta precisión en aplicaciones aeroespaciales, incluida la aviónica, los componentes estructurales y las piezas del motor, donde la confiabilidad y la seguridad son primordiales.

- Producción de dispositivos médicos: Garantiza una fijación de tornillos segura y constante en el ensamblaje de dispositivos y equipos médicos, donde la precisión y la higiene son fundamentales.

La máquina de bloqueo de tornillos de seis ejes ofrece una solución sofisticada para automatizar la fijación de tornillos en líneas de producción complejas. Con su movimiento robótico de seis ejes, control preciso del par y funciones avanzadas de monitorización, proporciona una solución flexible y de alto rendimiento para industrias que requieren un bloqueo de tornillos de alta precisión.