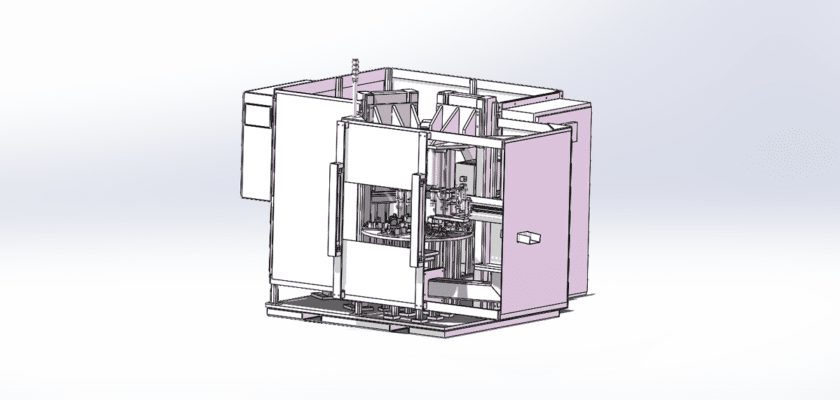

The drawing illustrates a Six-Station Assembly Machine, designed for efficient and automated assembly processes. This machine features six distinct stations, each dedicated to specific tasks in the assembly line, enhancing productivity and workflow.

Características principales:

- Modular Design: Each station can be configured for different assembly tasks, allowing for versatility in production.

- Automated Operations: Equipped with servo motors and programmable logic controllers (PLC), the machine automates repetitive tasks, reducing manual labor and increasing precision.

- Ergonomic Layout: The arrangement of stations is optimized for operator accessibility, minimizing movement and improving efficiency during operation.

- Safety Features: Integrated safety guards and emergency stop functions ensure a safe working environment for operators.

- Real-Time Monitoring: Sensors and display panels allow for real-time monitoring of the assembly process, facilitating quick adjustments and maintenance.

- Compatibility: Designed to accommodate various components and products, making it suitable for diverse manufacturing applications.

This drawing serves as a comprehensive guide for understanding the machine’s structure, functionality, and operational capabilities, making it an essential tool for engineers and operators in the assembly industry.