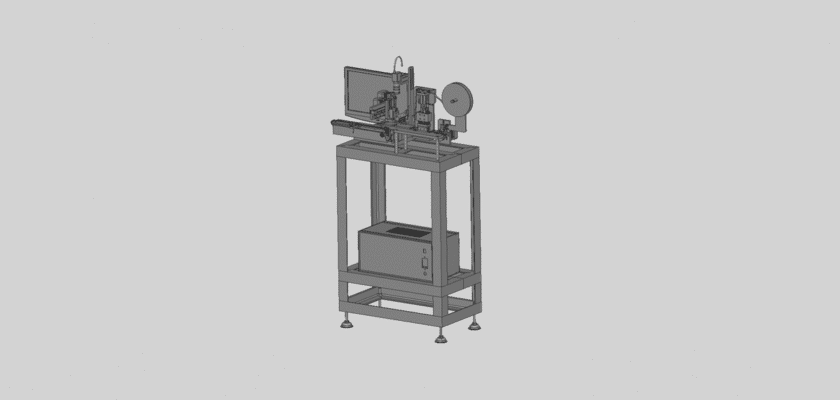

Explore the crucial process of electronic component packaging with our SMD Taping Machine drawing. This free resource is an invaluable asset for anyone in the electronics industry, from students learning about manufacturing processes to engineers designing production lines. The drawing provides a detailed look at a machine specifically engineered to automate the placement of surface-mount devices (SMDs) into tape-and-reel packaging. This method is the industry standard for transporting and feeding components to pick-and-place machines on SMT assembly lines. By downloading this drawing, you will gain a deep understanding of the machine’s mechanical operation, including the component feeding mechanism, the precise taping process, and the sealing system that prepares the reel for shipment. The design emphasizes speed, accuracy, and reliability, ensuring that even the most delicate and tiny components are packaged safely and efficiently. This drawing is an excellent educational tool and a practical reference for professionals seeking to optimize their electronics manufacturing processes.

Características principales:

- Automated Component Feeding: The machine is designed with a hopper or vibratory bowl system to automatically feed bulk components to the taping area, ensuring a continuous and high-speed operation.

- Precise Placement: A pick-and-place mechanism or similar system accurately positions each SMD into the pockets of the carrier tape, maintaining correct orientation and spacing for downstream assembly.

- Heat Sealing and Pressure Sealing: The drawing illustrates the two primary methods for securing the cover tape over the carrier tape’s pockets. Both heat sealing and pressure-sensitive adhesive sealing systems are used to protect components from damage and loss.

- Tape and Reel Handling: The design includes spools for managing both the carrier tape and cover tape, along with a winding mechanism to neatly roll the finished product onto a reel, ready for transport.

- Configurable and Versatile: The machine can be adjusted to handle various component sizes and types, as well as different tape widths, making it a highly adaptable tool for a wide range of electronic manufacturing needs.