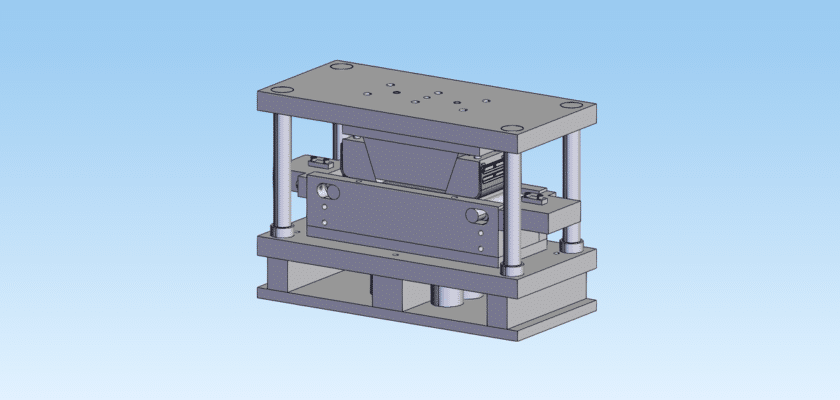

Master the complexity of multi-functional tooling with our Stamping and Bending Die technical drawing. In modern manufacturing, the ability to punch precise holes and immediately follow with a complex bend in the same toolset is critical for reducing part handling and maintaining tight tolerances. This CAD dibujo provides a comprehensive blueprint for a combined operation die, illustrating how to manage the high impact of “stamping” alongside the controlled material flow required for “bending.”

By downloading this resource, you can examine the mechanical synchronization required to prevent material distortion between stations. The layout features detailed views of the specialized “over-bend” geometry needed to account for material springback, as well as the reinforced punch retainers designed for high-tonnage piercing. This dibujo is particularly valuable for designers working on automotive brackets, electrical connectors, and structural clips where precision is non-negotiable. At MechStream, we provide these production-ready assets to help you optimize your press-room workflow and achieve perfect part geometry in every stroke.

Características principales:

- Integración de doble proceso: A specialized layout that handles both cutting and forming, reducing the need for secondary operations.

- Springback Compensation: Form blocks designed with calculated over-bend angles to ensure accurate final dimensions after the part is released.

- Hardened Tool Steel Inserts: Specifications for D2 or DC53 steel components to withstand the abrasive nature of both piercing and bending.

- Adjustable Stripper System: Features a heavy-duty pressure pad that keeps the material flat during stamping and serves as a holder during bending.

- Efficient Scrap Removal: Strategically placed slug chutes and relief holes to ensure cutting waste does not interfere with the forming stage.