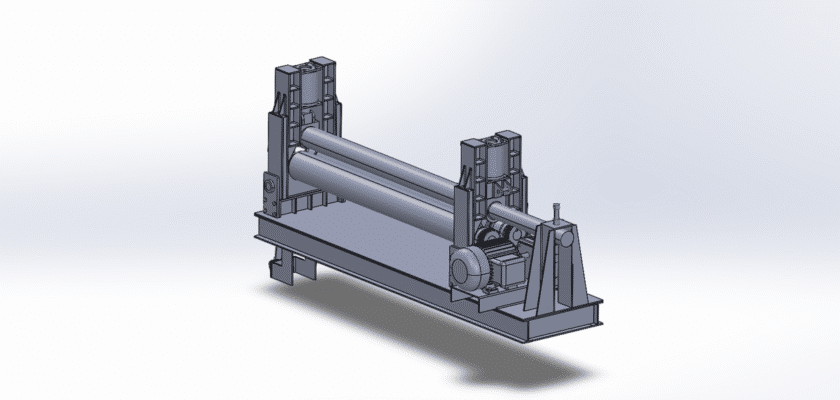

A steel plate roller press is a heavy-duty industrial machine used to bend and shape flat steel plates into various curved forms, such as cylinders, cones, and arcs. This process, known as rolling, is fundamental to manufacturing industries like shipbuilding, boiler making, and pipeline construction. By applying immense pressure through a series of rollers, the machine allows for the precise and consistent forming of large metal sheets without the need for heating. The comprehensive drawing available for free download provides a detailed blueprint of a professional-grade steel plate roller press. This invaluable resource is perfect for mechanical engineers, fabricators, and students who want to understand the intricate mechanical and hydraulic systems that enable such powerful metal forming. The plans illustrate the arrangement of the rollers, the hydraulic press cylinders, and the control mechanisms, giving you the knowledge to design or simply gain a deeper understanding of this essential piece of industrial equipment.

Características principales:

- High-Force Hydraulic System: The drawing details the powerful hydraulic cylinders that provide the massive force required to bend thick steel plates, showcasing their crucial role in the rolling process.

- Three-Roller Design: The blueprints highlight a three-roller configuration, the most common type, which allows for precise control over the curvature and radius of the final product.

- Robust & Rigid Frame: The machine is engineered with a heavy-duty, reinforced steel frame to withstand the immense forces and vibrations of the rolling process, ensuring long-term stability and accuracy.

- Control de velocidad variable: The design includes a system for adjusting the speed of the rollers, enabling operators to fine-tune the forming process for different material thicknesses and desired shapes.