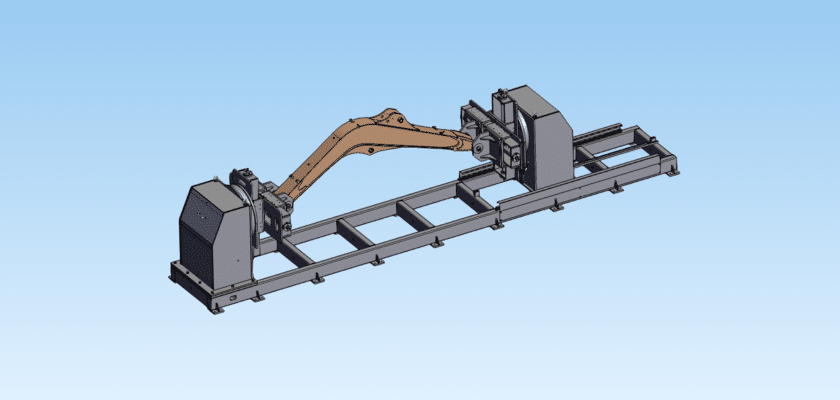

Maximize your fabrication efficiency for long, heavy workpieces with our exclusive, free drawing package Para el New Type Adjustable Head and Tailstock Welding Positioner! In industries such as truck frame manufacturing, pipeline construction, and large structural steel assembly, the ability to rotate long components for “down-hand” welding is absolutely critical. This new type of positioner features an innovative adjustable design, allowing for the distance between the motorized headstock and the idling tailstock to be quickly reconfigured to accommodate various part lengths. This flexibility ensures optimal welding ergonomics, increased safety, and superior weld quality by keeping every joint in the ideal position.

Este comprehensive technical drawing set provides the detailed blueprints for constructing a high-capacity, adjustable positioner system. The plans detail the heavy-duty structural columns, the precision motor-driven spindle of the headstock, the adjustable rail-mounted tailstock assembly, and the integrated synchronization controls. Welding engineers, machine builders, industrial plant managers, and mechanical designers will find these accurate, industry-standard drawings invaluable for building, maintaining, or customizing their large-scale material handling equipment. Stop struggling with cranes and manual flipping for long assemblies. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and highly versatile welding positioner. Secure your free positioner drawing now and rotate your production to success!

Características principales:

- Adjustable Rail-Mount System: Detailed blueprints of the floor-mounted rails and the locking mechanism that allows the tailstock to slide and secure at varying distances.

- Synchronized Motorized Drive: Schematics illustrating the heavy-duty AC/DC gear motor and VFD (Variable Frequency Drive) setup for smooth, variable-speed rotation of the headstock.

- Precision Head and Tailstock Spindles: Drawings detailing the oversized bearings and hollow-bore spindle designs capable of supporting massive cantilevered and axial loads.

- Height Adjustment Capability: Blueprints showing the optional motorized or manual lifting columns used to adjust the rotational centerline height for large-diameter workpieces.

- Integrated Earthing System: Details on the high-current rotary grounding brushes designed to allow welding current to pass safely through the positioner without damaging bearings.