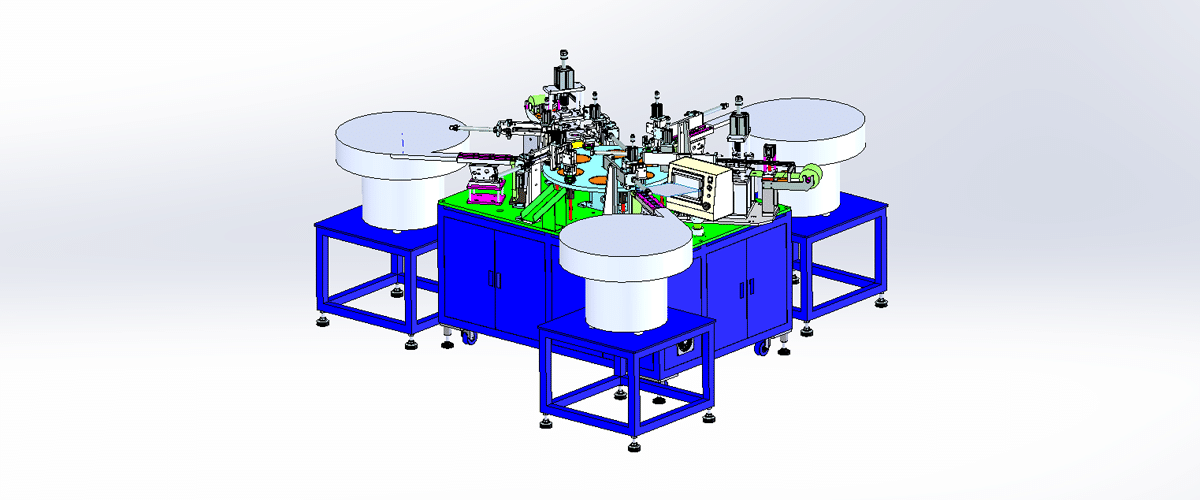

En Three-Layer Cover Automatic Assembly Machine is designed for the efficient and precise assembly of multi-layer protective covers used in various applications. This machine integrates advanced automation technology to streamline the assembly process, ensuring high production rates and consistent quality.

Características principales:

- Multi-Layer Assembly: Capable of assembling three distinct layers simultaneously, improving efficiency and reducing cycle time.

- Automatic Feed System: Equipped with an automated feeding mechanism that ensures a continuous supply of materials, minimizing downtime.

- Precision Alignment: Features advanced alignment systems to ensure accurate positioning of each layer, enhancing the quality of the final product.

- Interfaz fácil de usar: Includes an intuitive control panel for easy operation and monitoring of the assembly process.

- Safety Measures: Designed with safety guards and emergency stop functions to protect operators during operation.

- Compact Design: Optimized layout for space-saving in manufacturing facilities while maintaining high output.

Applications:

- Ideal for the production of covers in electronics, automotive, and consumer goods industries.

This drawing will illustrate the machine’s layout, component placement, and operational flow, providing a comprehensive overview for manufacturing and assembly purposes.