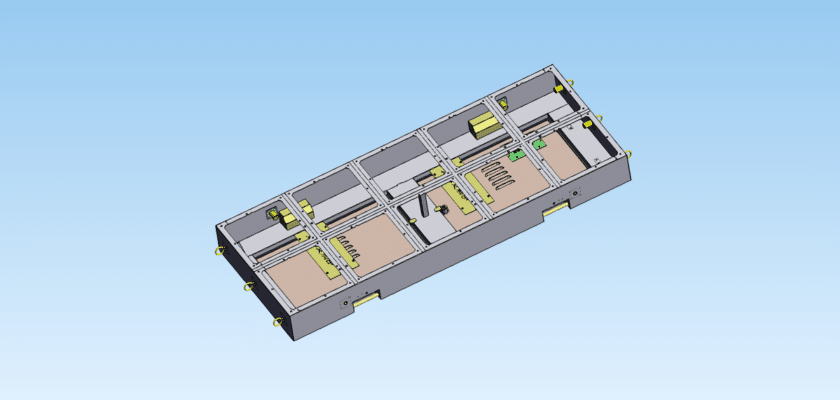

En Vertical Welding Tilting and Positioning Machine is a heavy-duty industrial solution designed to provide a full range of motion for workpieces that require complex, multi-angle weld paths. This professional 3D model illustrates a robust machine architecture featuring a primary vertical column that supports a tilting arm and a high-torque rotary table. This configuration allows the workpiece to be rotated $360^{\circ}$ while simultaneously being tilted up to $135^{\circ}$ or more, ensuring that even the most difficult-to-reach internal or external seams are positioned for optimal “downhand” gravity-assisted welding.

By downloading this comprehensive 3D model, you gain access to a high-fidelity assembly that includes the mechanical drive train, the worm-gear tilting mechanism, and the precision-machined faceplate. The model is meticulously constrained to reflect real-world kinematics, allowing you to simulate the machine’s range of motion within your digital factory layout. This is particularly valuable for verifying “swing clearances” for large workpieces and ensuring that robotic welding arms have unobstructed access to the entire weldment without collision.

This engineering resource is optimized for structural analysis and integration. The 3D model includes detailed internal components such as high-capacity slewing bearings and the electrical grounding system, which is crucial for protecting the machine’s electronics from high welding currents. Utilizing this pre-verified 3D geometry allows your team to skip the time-consuming modeling of standard industrial equipment and focus on the design of custom jigs and the optimization of automated welding cycles.

Características principales:

- Dual-Axis Kinematic Freedom: Fully articulated 3D assembly in the modelo providing precise rotational and tilting movements.

- Heavy-Duty Vertical Pedestal: A reinforced column design engineered to maintain absolute stability under high-moment loads and eccentric weights.

- Integrated T-Slot Faceplate: A standardized mounting surface designed for the rapid attachment of custom fixtures, chucks, or clamps.

- Automated Drive Specifications: Pre-defined mounting locations for servo motors or variable frequency drives (VFD) for synchronized motion control.

- High-Current Grounding Path: Strategic electrical conduction logic designed to bypass precision bearings and prevent mechanical arcing.