Mejore sus conocimientos de ingeniería y sus capacidades de fabricación descargando nuestro plano detallado gratuito de una máquina de inspección visual. Estos sistemas avanzados están revolucionando el control de calidad en diversas industrias, desde la farmacéutica y la electrónica hasta la alimentaria y la automotriz. Una máquina de inspección visual utiliza una combinación de cámaras de alta resolución, iluminación especializada y un software sofisticado para inspeccionar automáticamente los productos en busca de defectos, imperfecciones o inconsistencias que a menudo son invisibles al ojo humano. Esta automatización garantiza una precisión y consistencia inigualables, lo que ayuda a los fabricantes a reducir el desperdicio, mejorar la seguridad de los productos y aumentar la eficiencia de la producción.

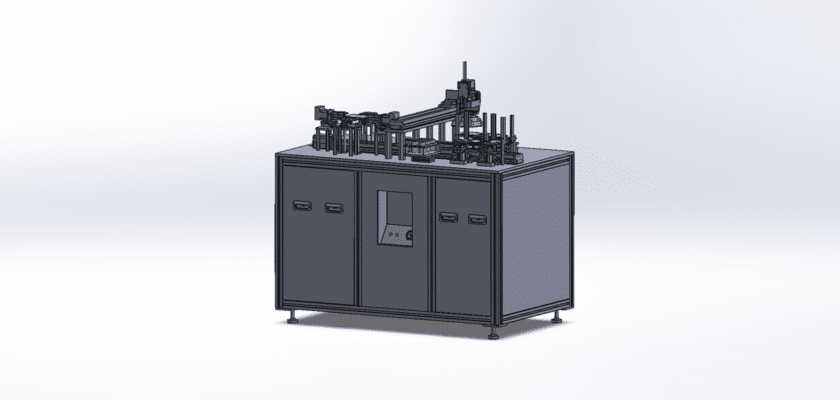

Este dibujo CAD es un recurso esencial para estudiantes, ingenieros y diseñadores que desean comprender los complejos componentes y principios operativos de los sistemas de inspección automatizada. Ofrece una visión clara y completa de cómo la visión artificial se integra con los sistemas de manipulación mecánica para realizar controles de calidad rápidos y no destructivos. Al estudiar este dibujo, podrá comprender mejor el diseño del soporte de la cámara, las configuraciones de iluminación y los mecanismos de manipulación del producto, cruciales para la inspección de alta velocidad. Este valioso recurso técnico está listo para integrarse en su próximo proyecto o estudio, ofreciendo una ventaja clave en el mundo de la fabricación de alta precisión.

Características principales:

- Análisis automatizado de alta velocidad: La función principal de la máquina es realizar inspecciones a la velocidad de la línea de producción, superando ampliamente la capacidad y la consistencia de la inspección manual y permitiendo realizar controles de calidad 100% sin ralentizar el proceso de fabricación.

- Detección versátil de defectos: Utilizando una combinación de óptica avanzada y algoritmos de procesamiento de imágenes, la máquina puede detectar una amplia gama de defectos, incluidos rayones en la superficie, etiquetado incorrecto, errores dimensionales, componentes faltantes y contaminantes extraños.

- Mayor precisión y confiabilidad: A diferencia de los inspectores humanos, que pueden sufrir fatiga y subjetividad, una máquina de inspección visual proporciona resultados objetivos y repetibles, garantizando que cada producto cumpla con exactamente el mismo estándar de calidad.

- Mejora de la calidad basada en datos: El sistema recopila y registra datos detallados sobre los defectos detectados, proporcionando información valiosa que puede utilizarse para identificar y corregir problemas en el proceso de fabricación, lo que conduce a una mejora continua y a mayores rendimientos a lo largo del tiempo.