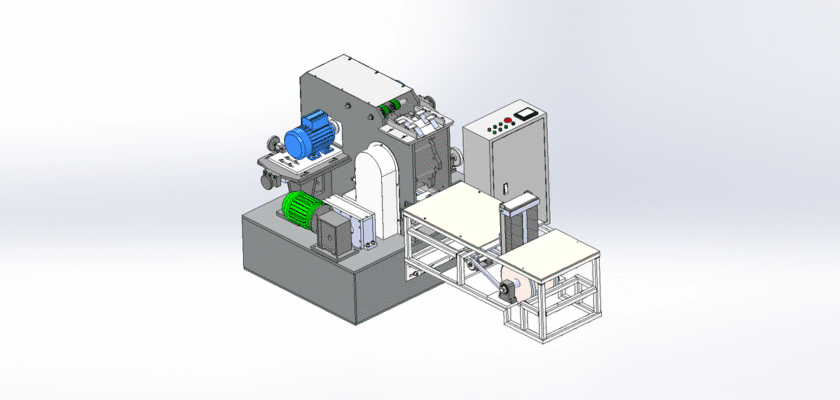

Encienda sus proyectos de carpintería con nuestro Dibujo gratuito de equipo automático de corte y conformado de maderaEste detallado archivo CAD es un recurso esencial para ingenieros, ebanistas y fabricantes de las industrias del mueble y la construcción. El plano ofrece una visión completa de una máquina especializada diseñada para cortar y conformar automáticamente piezas de madera con alta precisión y consistencia. Al automatizar este proceso, puede reducir significativamente el tiempo de producción, minimizar el desperdicio de material y garantizar una calidad uniforme en todos sus productos.

El plano destaca los complejos mecanismos de la máquina, incluyendo el sistema de alimentación automatizado, la sierra o fresadora de alta velocidad y el brazo robótico o pórtico que da forma a la madera según un diseño preprogramado. Comprender estos componentes es fundamental para lograr un alto rendimiento y diseños complejos. El diseño está optimizado para un funcionamiento continuo a alta velocidad, lo que lo hace ideal para la producción en masa de piezas de muebles, paneles decorativos o componentes estructurales. Ya sea que esté construyendo una nueva estación de carpintería, actualizando equipos existentes o estudiando los principios de la automatización industrial, este plano le proporciona la información técnica que necesita. Es una herramienta perfecta tanto para estudiantes como para profesionales, ya que ofrece una visión detallada del futuro de la carpintería automatizada.

Características principales:

- Corte y conformado automatizados: El dibujo detalla una única máquina que realiza tanto el corte como el conformado, agilizando el proceso de carpintería.

- Herramientas de alta precisión: Se muestra el diseño de las herramientas de corte y conformado, que están diseñadas para realizar cortes precisos y limpios en varios tipos de madera.

- Sistema de alimentación integrado: El plano incluye el diseño del sistema automatizado que garantiza un suministro continuo de madera a la máquina.

- Diseño versátil: La máquina se puede programar para manejar una amplia gama de tamaños y formas de madera, lo que la convierte en una solución flexible para diversos proyectos.

- Especificaciones técnicas: Incluye dimensiones y especificaciones críticas para los componentes de la máquina, lo que la hace adecuada para fines de diseño y referencia.