Compensate for positional inaccuracies and prevent mechanical binding with our professional XY Floating Mechanism drawing. In high-precision automation, even a 0.1mm offset between a tool and a workpiece can lead to jammed parts, broken pins, or structural wear. This technical CAD resource provides a blueprint for a “compliance” mechanism that allows a tool or fixture to shift slightly in the X and Y planes to find its own center during engagement. By downloading this file, you gain access to a design that ensures smooth insertion and assembly, even when the robot or gantry positioning is not perfectly concentric.

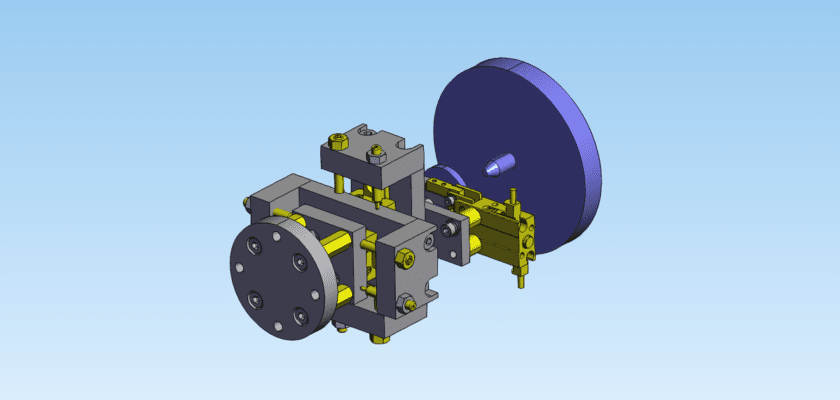

The design featured in this package focuses on the Spring-Centered Linear Slide architecture. The drawing includes detailed layouts for two layers of orthogonal precision slides—one for the X-axis and one for the Y-axis—coupled with calibrated centering springs. These springs return the mechanism to a “neutral” home position after every cycle, while the low-friction bearings allow for effortless movement during the “floating” phase. By utilizing this blueprint from MechStream, you can significantly reduce the “stiffness” of your automation, protecting both the product and the machine from excessive lateral forces.

Our technical documentation prioritizes repeatability and damping. The assembly is designed with adjustable spring pre-load and integrated hard-stops to limit the maximum float range, preventing the mechanism from over-traveling. Whether you are building an automated screw-driving station, a PCB testing jig, or a heavy-duty pallet docking station, this drawing provides the exact material specifications, bearing load ratings, and centering force calculations required for a professional-grade installation.

Características principales:

- True Orthogonal Movement: Features two independent axes of travel to provide 360-degree lateral compensation.

- Calibrated Self-Centering: Utilizes high-durability springs to ensure the mechanism always returns to the theoretical center after the load is removed.

- Ultra-Low Friction Interface: Detailed specifications for linear ball bushings or cross-roller guides to ensure smooth movement even under axial load.

- Adjustable Float Range: Includes mechanical limiters to restrict the displacement to the specific requirements of your assembly process (e.g., ±2.0mm).

- High Axial Rigidity: Engineered to withstand high Z-axis press forces while remaining flexible in the XY plane.