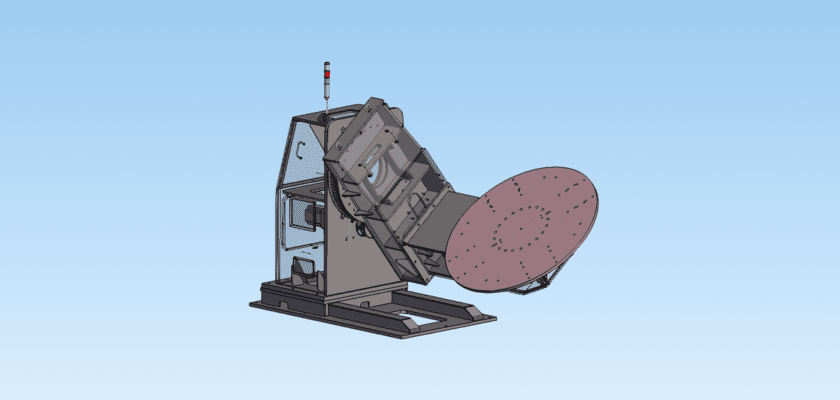

Handle your heavy and bulky fabrications with confidence using our exclusive, free drawing package pour le 2.5-Ton L-Type Welding Positioner! Designed for massive workloads, this positioner is an absolute essential for industries like heavy construction, shipbuilding, and large machinery manufacturing. The L-Type configuration is particularly advantageous as it allows for significant vertical and horizontal manipulation of components weighing up to 2.5 metric tons, ensuring that even the most complex, multi-sided assemblies can be quickly brought into the optimal, high-quality ‘down-hand’ welding position.

Ce comprehensive technical drawing set provides the detailed blueprints for the entire heavy-duty structure. The plans detail the powerful dual-axis drive systems, the massive slew rings and bearings required for handling eccentric loads, and the structural integrity of the robust frame designed for maximum stability. Structural engineers, heavy fabricators, and equipment designers will find these accurate, industry-standard drawings essential for building, integrating, or specifying positioners for extreme loads. Stop compromising on safety and weld quality when handling large components. By downloading this critical design asset today, you gain the foundational technical knowledge for mastering heavy-duty fabrication equipment. Secure your free positioner drawing now and effortlessly manage your 2.5-ton assemblies!

Caractéristiques principales :

- 2.5-Ton Load Capacity: Detailed structural drawings ensuring the frame, bearings, and drive systems meet the high-load requirements for this specific weight class.

- L-Type Dual-Axis System: Blueprints illustrating the powerful drive mechanisms that allow both faceplate rotation et arm tilting (pitch/roll) for comprehensive workpiece access.

- Heavy-Duty Slewing Drives: Schematics detailing the gearing, motors, and brakes required to safely and precisely control the movement of heavy, eccentric loads.

- Massive Faceplate Design: Drawings specifying the dimensions and material of the faceplate, typically featuring reinforced T-slots for secure and customizable mounting of large fixtures.

- Fonctionnalités de sécurité intégrées : Details on the robust limit switches, emergency stops, and hydraulic/mechanical locking systems crucial for safe operation under heavy loads.