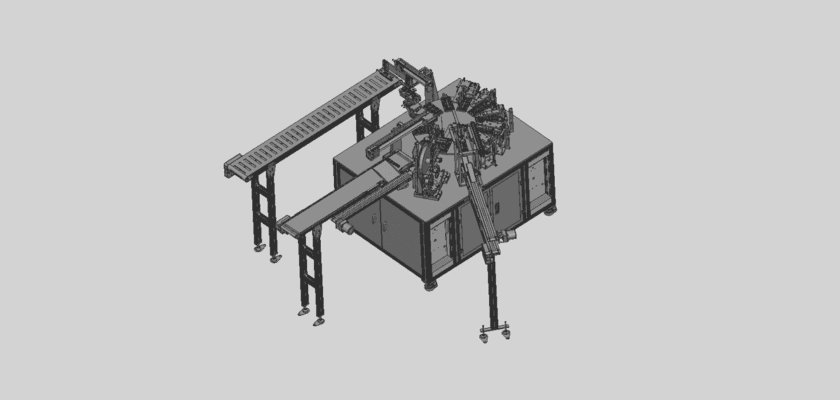

Un Dessin d'une machine de fixation automatique de moules d'essai is a technical illustration that outlines the design and functionality of a machine specifically engineered for the automated attachment of test molds to various products or components. This type of machine is crucial in industries such as electronics, automotive, and manufacturing, where precision in mold attachment is essential for quality assurance and testing purposes.

Caractéristiques principales :

- Disposition générale: A detailed view of the machine’s structure, showcasing the arrangement of components and their interactions throughout the mold attaching process.

- Système d'alimentation des produits: Diagrams illustrating the mechanisms that transport products to the mold attaching area, which may include conveyor belts or automated feeders to ensure a continuous flow of items.

- Mold Handling System: Representation of the systems that manage the loading and positioning of test molds, including automated pick-and-place mechanisms or robotic arms designed for precise placement.

- Mécanisme de fixation: Information about the system that applies the molds, detailing how the molds are securely attached to the products (e.g., through clamping, adhesives, or other methods).

- Panneau de contrôle:Illustrations de l'unité de contrôle centrale qui gère le fonctionnement de la machine, permettant aux opérateurs de surveiller les processus, d'ajuster les paramètres et d'accéder aux données de performance en temps réel.

- Interface utilisateur: Details about the touchscreen or control panel that provides operators with intuitive access to machine settings, including mold types, application speed, and other parameters.

- Systèmes de contrôle de la qualité: Diagrams showing integrated sensors or cameras that monitor the attaching process for accuracy, ensuring that each mold is positioned correctly.

- Systèmes de sortie de données: Information on how production data, including mold attachment counts and quality metrics, are logged and communicated, featuring digital displays for immediate feedback.

- Cadre mécanique: Détails sur les composants structurels qui soutiennent la machine, assurant la stabilité et la précision pendant le fonctionnement.

- Caractéristiques de sécurité: Information regarding safety mechanisms, such as emergency stops, safety guards, and sensors to ensure safe operation throughout the mold attaching process.

- Alimentation électrique:Informations sur les exigences électriques et les systèmes de secours pour assurer un fonctionnement fiable.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of automatic test mold attaching machines, ensuring high standards of efficiency, accuracy, and operational effectiveness in the testing process.