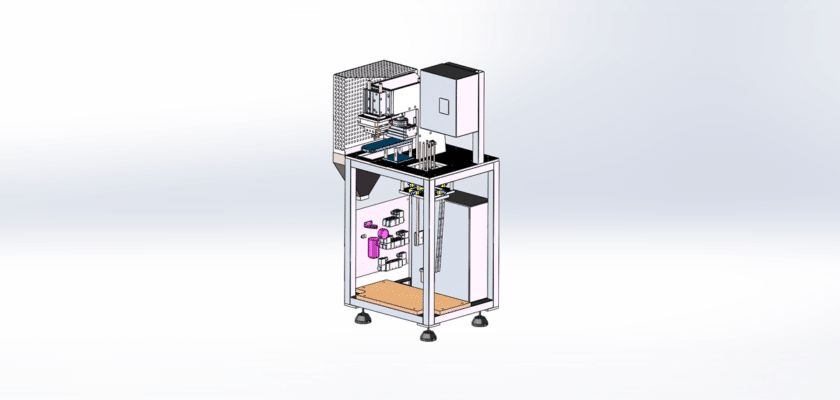

A Glove Thermal Transfer Film Hot Stamping Machine Drawing is a detailed technical illustration that outlines the design, components, and functionality of a machine specifically designed for hot stamping graphics or text onto gloves using thermal transfer film. This drawing is essential for engineers, technicians, and operators involved in the machine’s design, assembly, and maintenance.

Caractéristiques principales :

- Disposition générale: A comprehensive view of the machine’s structure, showcasing the arrangement of major components, including the infeed, stamping area, and outfeed sections.

- Hot Stamping Mechanism: Detailed illustrations of the stamping technology used, including:

- Heated Stamping Plate: A component that applies heat and pressure to transfer the film onto the glove material.

- Film Feed System: Mechanisms that supply the thermal transfer film to the stamping area.

- Glove Handling System: Diagrams showing how gloves are positioned for stamping, which may include fixtures or jigs that ensure proper alignment and stability during the process.

- Système de contrôle: Information about the central control unit that manages the stamping process, allowing operators to monitor settings, adjust parameters, and access real-time performance data.

- Interface utilisateur: Details on the touchscreen or control panel that provides intuitive access to machine settings, including temperature control, stamping pressure, and operational modes.

- Circuit de refroidissement: Illustrations of components that cool the stamped area after the hot stamping process, ensuring that the gloves can be handled safely and efficiently.

- Fonctionnalités de contrôle qualité: Diagrams showing integrated sensors that monitor the stamping quality, ensuring that prints meet specifications and that any issues are detected early.

- Caractéristiques de sécurité:Informations sur les mécanismes de sécurité, tels que les arrêts d'urgence, les dispositifs de sécurité et les verrouillages qui garantissent un fonctionnement sûr pendant le processus d'emboutissage.

- Cadre mécanique: Détails sur les composants structurels qui soutiennent la machine, assurant stabilité et durabilité lors des opérations à grande vitesse.

- Points d'accès de maintenance:Conseils sur les zones conçues pour un accès facile pendant la maintenance et la réparation, facilitant un entretien efficace de l'équipement.

This drawing serves as a crucial reference for anyone involved in the operation and maintenance of glove thermal transfer film hot stamping machines, ensuring effective performance, efficiency, and adherence to industry standards in the glove manufacturing and branding processes.