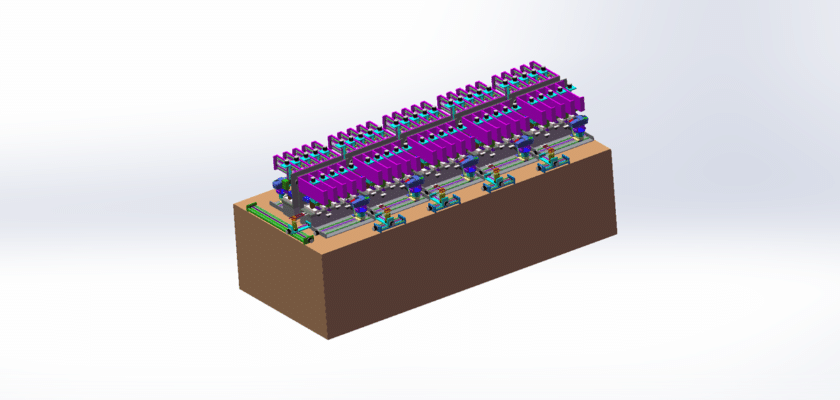

Un dessin de tampographie multiposte est une illustration technique détaillée décrivant la conception, les composants et le fonctionnement d'une machine de tampographie multiposte. Ce dessin est essentiel pour les ingénieurs, techniciens et opérateurs impliqués dans la conception, l'assemblage et la maintenance de la machine.

Caractéristiques principales :

- Disposition générale:Une vue complète de la structure de la machine, présentant la disposition de plusieurs stations d'impression, du panneau de commande et des systèmes de manutention des matériaux.

- Mécanisme de tampographie:Illustrations détaillées de la technologie de tampographie, notamment :

- Porte-tampon:Composants qui fixent les tampons en silicone utilisés pour transférer l'encre sur les substrats.

- Tasse d'encre:Le système qui retient et alimente les tampons en encre, garantissant une application uniforme pendant l'impression.

- Conception multi-stations:Schémas illustrant le fonctionnement de chaque poste d'impression, qui peuvent inclure :

- Impression simultanée: Détails sur la façon dont plusieurs blocs peuvent imprimer différents motifs ou couleurs en même temps, améliorant ainsi la productivité.

- Commutation automatique:Mécanismes permettant des transitions transparentes entre les opérations d'impression à différentes stations.

- Système de contrôle:Informations sur l'unité de contrôle centrale qui gère le processus d'impression sur toutes les stations, permettant aux opérateurs de surveiller les paramètres, d'ajuster les paramètres et d'accéder aux données de performances en temps réel.

- Interface utilisateur: Détails sur l'écran tactile ou le panneau de commande qui offrent un accès intuitif aux paramètres de la machine, y compris la vitesse d'impression, les réglages d'enregistrement et les modes de fonctionnement pour chaque station.

- Système de manutention:Illustrations de la manière dont les substrats (par exemple, plastiques, céramiques) sont introduits et sortis de chaque station d'impression, y compris les convoyeurs ou les systèmes d'indexation qui garantissent un alignement correct et un flux de travail efficace.

- Système de séchage ou de durcissement:Composants conçus pour sécher ou durcir les matériaux imprimés, qui peuvent inclure des radiateurs infrarouges ou des unités de durcissement UV pour garantir un traitement rapide.

- Fonctionnalités de contrôle qualité: Diagrammes montrant des capteurs intégrés et des systèmes de surveillance qui garantissent la qualité et la cohérence de l'impression sur toutes les stations.

- Caractéristiques de sécurité: Informations sur les mécanismes de sécurité, tels que les arrêts d'urgence, les dispositifs de sécurité et les verrouillages qui garantissent un fonctionnement sûr pendant les processus d'impression.

- Cadre mécanique: Détails sur les composants structurels qui soutiennent la machine, assurant stabilité et durabilité lors des opérations à grande vitesse.

- Points d'accès de maintenance:Conseils sur les zones conçues pour un accès facile pendant la maintenance et la réparation, facilitant un entretien efficace de l'équipement.

Ce dessin sert de référence essentielle pour toute personne impliquée dans l'exploitation et la maintenance d'imprimantes à tampon multi-stations, garantissant des performances efficaces, une efficacité et le respect des normes de l'industrie dans diverses applications d'impression.