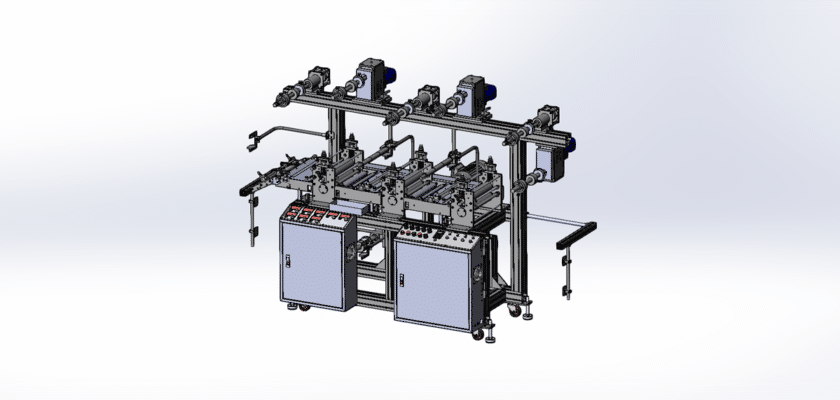

The Three-Seat Die Cutting and Laminating Machine is an advanced industrial tool designed to streamline the die-cutting and laminating processes in various manufacturing industries. This machine integrates both die-cutting and laminating functions into one efficient unit, making it ideal for industries that require high precision, such as packaging, electronics, and automotive parts production.

The machine is equipped with three working seats, allowing for simultaneous processing of multiple materials, which significantly increases productivity and reduces cycle times. It efficiently handles a wide range of materials, including paper, plastic, rubber, and textiles, offering versatile applications for creating intricate shapes and laminated products.

With its robust design, the Three-Seat Die Cutting and Laminating Machine ensures precise cuts and uniform laminations, meeting the high standards required in modern manufacturing. The easy-to-operate control system allows for quick adjustments to cutting pressure, speed, and temperature, ensuring optimal results for different material types and thicknesses.

The machine’s high efficiency reduces labor costs and operational downtime, making it an excellent choice for high-volume production environments. Its durable construction and reliable performance guarantee long-lasting use, even in demanding industrial settings.

For businesses looking to optimize their die-cutting and laminating processes, this machine offers a cost-effective and space-saving solution, boosting production capacity while maintaining high-quality standards. Whether used for packaging, automotive, or electronics applications, the Three-Seat Die Cutting and Laminating Machine provides reliable, fast, and precise results.