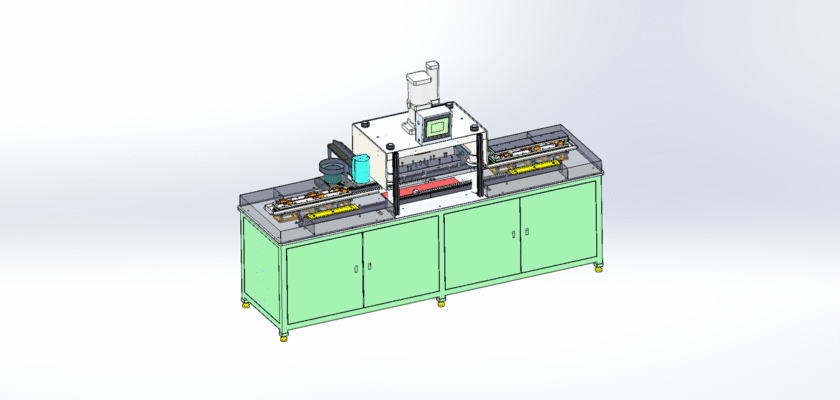

Elevate your assembly processes with our powerful Riveting Stud Machine drawing. This free, detailed blueprint is an essential resource for engineers, designers, and manufacturers seeking to master the principles of automated fastening. A riveting stud machine is a specialized piece of industrial equipment designed to quickly and securely attach threaded studs to sheet metal panels without welding or separate fasteners. This process is crucial in industries like automotive, electronics, and appliance manufacturing, where strong, permanent, and consistent joints are required for components like control panels, chassis, and brackets. Our meticulously crafted drawing provides an in-depth look at the machine’s inner workings, including its automatic stud feeding mechanism, pneumatic or hydraulic actuation, and precision tooling. Downloading this blueprint will give you the knowledge to understand, design, or optimize riveting equipment, empowering you to improve efficiency and quality in your own production lines.

Caractéristiques principales :

- High-Speed Automation: Designed for rapid, continuous fastening cycles, significantly increasing production throughput.

- Consistent Joint Strength: The mechanism ensures uniform crimping or cold forming, creating a reliable and permanent connection.

- Versatile Tooling: The design can be adapted to handle a variety of stud diameters and lengths, as well as different sheet material thicknesses.

- Integrated Safety Systems: Includes design features to protect operators and prevent machine damage during operation.

- Automated Feeding System: The blueprint details a reliable hopper and track system for continuously feeding studs to the riveting head.